Blog

Mechanical Marvels

Each one of these devices uses mechanical principles to achieve a function. Some objects are “consumer end products,” and others are “behind the scenes” mechanisms necessary to create the wonderful tools and devices that make our lives comfortable, productive, and efficient. You’ll see more examples of these mechanical principles that were modified, utilized, and refined to achieve the successes of the industrial revolution and modern applications of science and technology. Let’s move, turn, and explore these Marvelous Mechanisms and ponder how they work, what principles of mechanics they apply, and how the innovations drove industry.

Almond Right Angle Drive (1880s)

Power transmission is an important part of any manufacturing operation. The Almond Drive was developed to reduce maintenance costs and noise involved in power transmission. It changes the direction of the motion by 90° without gears. The transmission is intended to be mounted on a ceiling, so it does not take up floor space.

Power transmission is an important part of any manufacturing operation. The Almond Drive was developed to reduce maintenance costs and noise involved in power transmission. It changes the direction of the motion by 90° without gears. The transmission is intended to be mounted on a ceiling, so it does not take up floor space.

Sewing Machine

Sewing machines have a fascinating and storied history to tell. In the late 1700s, a British cabinet maker designed a machine for sewing leather. In the 1830s, a French tailor and inventor had come up with a successful design but was run out of town by seamstresses afraid of losing their jobs to this “automatic machine.” Through the 19th and into the 20th century, there were hundreds of sewing machine manufacturers and designs. From 1858 to 1860, a Family machine was made in Brattleboro, Vermont. It sold for about $10, which is around $350 today. Jones and Lamson; Lamson, Goodnow, and Yale; and Vermont Arms Co. produced the Windsor from about 1856 to 1861.

This machine is called a New England. It was a simple hand-crank model that was probably made by Samuel Barker and Thomas White. White would later buy the rights to produce the Clarke’s Revolving Looper, made by Lamson, Goodnow, and Yale right here in Windsor.

Rose Engine (1870-1899)

A specialized lathe is used to make complex geometric patterns, most often decorative. This one operates much like a spirograph. By setting the axis of one rotation off and away from another, it will create arcs instead of true circles.

Profiling Machine (1900-1920)

It is incredibly hard to make small components with a high degree of precision. This machine uses a pin in the front to trace a metal pattern. The motions and pathways are transferred and repeated through parallel joints. A cutting tool on a stock piece of material follows that pattern. The relative distances of the pivots will dictate the scale of the part.

It is incredibly hard to make small components with a high degree of precision. This machine uses a pin in the front to trace a metal pattern. The motions and pathways are transferred and repeated through parallel joints. A cutting tool on a stock piece of material follows that pattern. The relative distances of the pivots will dictate the scale of the part.

Oliver Typewriter (1905-1920)

Commercial typewriters came into production in the late 1800s. Over the turn of the century, there were many manufacturers and designs. In order to produce a “user-friendly” device, many complex operations and intricate parts needed to be assembled with a high degree of precision. Many tools and techniques developed and improved in gun making, clockwork, and similar operations were employed in making typewriters.

Commercial typewriters came into production in the late 1800s. Over the turn of the century, there were many manufacturers and designs. In order to produce a “user-friendly” device, many complex operations and intricate parts needed to be assembled with a high degree of precision. Many tools and techniques developed and improved in gun making, clockwork, and similar operations were employed in making typewriters.

Key Cutter (1920-1930)

Much like the one you see at a modern hardware store, this cutter follows the profile of an existing key as it cuts a blank key.

Much like the one you see at a modern hardware store, this cutter follows the profile of an existing key as it cuts a blank key.

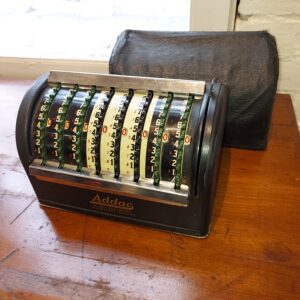

Adding Machine

On the face of it, this is simply a useful tool for adding and subtracting. Imagine the inner workings of this device and consider the complexities of the mechanisms necessary to make it work reliably and with ease.

On the face of it, this is simply a useful tool for adding and subtracting. Imagine the inner workings of this device and consider the complexities of the mechanisms necessary to make it work reliably and with ease.

Ribbon Winding Machine

This is a commercial solution to rapidly counting the length of ribbon as it gets wound onto an empty spool before being sold to the customer. As you wind the ribbon onto the spool, the counter shows you how many yards have been wound. The circumference of the counting wheel is 18 inches.

This is a commercial solution to rapidly counting the length of ribbon as it gets wound onto an empty spool before being sold to the customer. As you wind the ribbon onto the spool, the counter shows you how many yards have been wound. The circumference of the counting wheel is 18 inches.

Player Piano Air Pump

A piano is a true “Mechanical Marvel” with many delicately balanced and levered components. A player-piano takes advantage of this by adding “actuators,” which control a moving part. The actuators get their instructions from a series of carefully placed holes in a paper roll passed over a manifold with a row of holes called a tracker bar. In a player piano, notes are triggered by a vacuum. This air pump is used to provide suction to the vacuum. The bellows create the vacuum in the tracker bar, and the holes release that pressure, which then activates the keys. This pump has five bellows that all operate at separate times to maintain a vacuum in the system.

A piano is a true “Mechanical Marvel” with many delicately balanced and levered components. A player-piano takes advantage of this by adding “actuators,” which control a moving part. The actuators get their instructions from a series of carefully placed holes in a paper roll passed over a manifold with a row of holes called a tracker bar. In a player piano, notes are triggered by a vacuum. This air pump is used to provide suction to the vacuum. The bellows create the vacuum in the tracker bar, and the holes release that pressure, which then activates the keys. This pump has five bellows that all operate at separate times to maintain a vacuum in the system.

Index Plate

Circles are remarkable shapes if you think about them. A single perfect circle represents the maximum area available within a set perimeter. Creating precise circles and dividing them incrementally is a significant feat in manufacturing. This is necessary for manufacturing; consider gears, spokes, bearings, and other circular components. They can be measured and divided in many ways (degrees, radians, circumference and more.) To do so accurately requires a very precise “ruler” of sorts.

Circles are remarkable shapes if you think about them. A single perfect circle represents the maximum area available within a set perimeter. Creating precise circles and dividing them incrementally is a significant feat in manufacturing. This is necessary for manufacturing; consider gears, spokes, bearings, and other circular components. They can be measured and divided in many ways (degrees, radians, circumference and more.) To do so accurately requires a very precise “ruler” of sorts.

Rotary Table

We often take the action of rotation for granted. When something doesn’t rotate “perfectly,” we can see and feel the difference. Many machine operations are on linear axes, meaning back and forth, up and down, etc., in a straight line. Try creating a circle with only small, incremental linear motions. It’s almost impossible! This work table can be attached to a machine to allow circles and round features to be more easily and precisely created.

We often take the action of rotation for granted. When something doesn’t rotate “perfectly,” we can see and feel the difference. Many machine operations are on linear axes, meaning back and forth, up and down, etc., in a straight line. Try creating a circle with only small, incremental linear motions. It’s almost impossible! This work table can be attached to a machine to allow circles and round features to be more easily and precisely created.

Mystery Machine

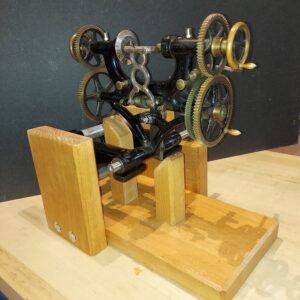

With many of these “Mechanical Marvels” we can observe processes like transfer of motion from rotational to linear, repeatable precision; cams, followers, slides, and ways. Some machines are “universal,” meaning they can be set up for various operations. Others are very specific in their utility and purpose. This device has many features that speak to its functions. This machine was a gift to a museum staff member from a friend who said, “I’ve had this for long enough, now you can have it.” So far, nobody has been able to identify exactly what it is.

With many of these “Mechanical Marvels” we can observe processes like transfer of motion from rotational to linear, repeatable precision; cams, followers, slides, and ways. Some machines are “universal,” meaning they can be set up for various operations. Others are very specific in their utility and purpose. This device has many features that speak to its functions. This machine was a gift to a museum staff member from a friend who said, “I’ve had this for long enough, now you can have it.” So far, nobody has been able to identify exactly what it is.

What can you discern from these features and motions? What was its purpose?

What tools and equipment are similar looking and different, and in what ways?

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact