Blog

Machine of the Month: What is that? Part II

We have this cylindrical saw that’s 13 ½” in diameter. Naturally, everyone who sees it thinks, “giant hole saw.” But it’s probably not. A number of years ago, a visitor suggested that it was to produce discs. That’s probably so. We have since seen a keg with a head (a disc) that’s 13 ¼” in diameter; we take that as confirmation.

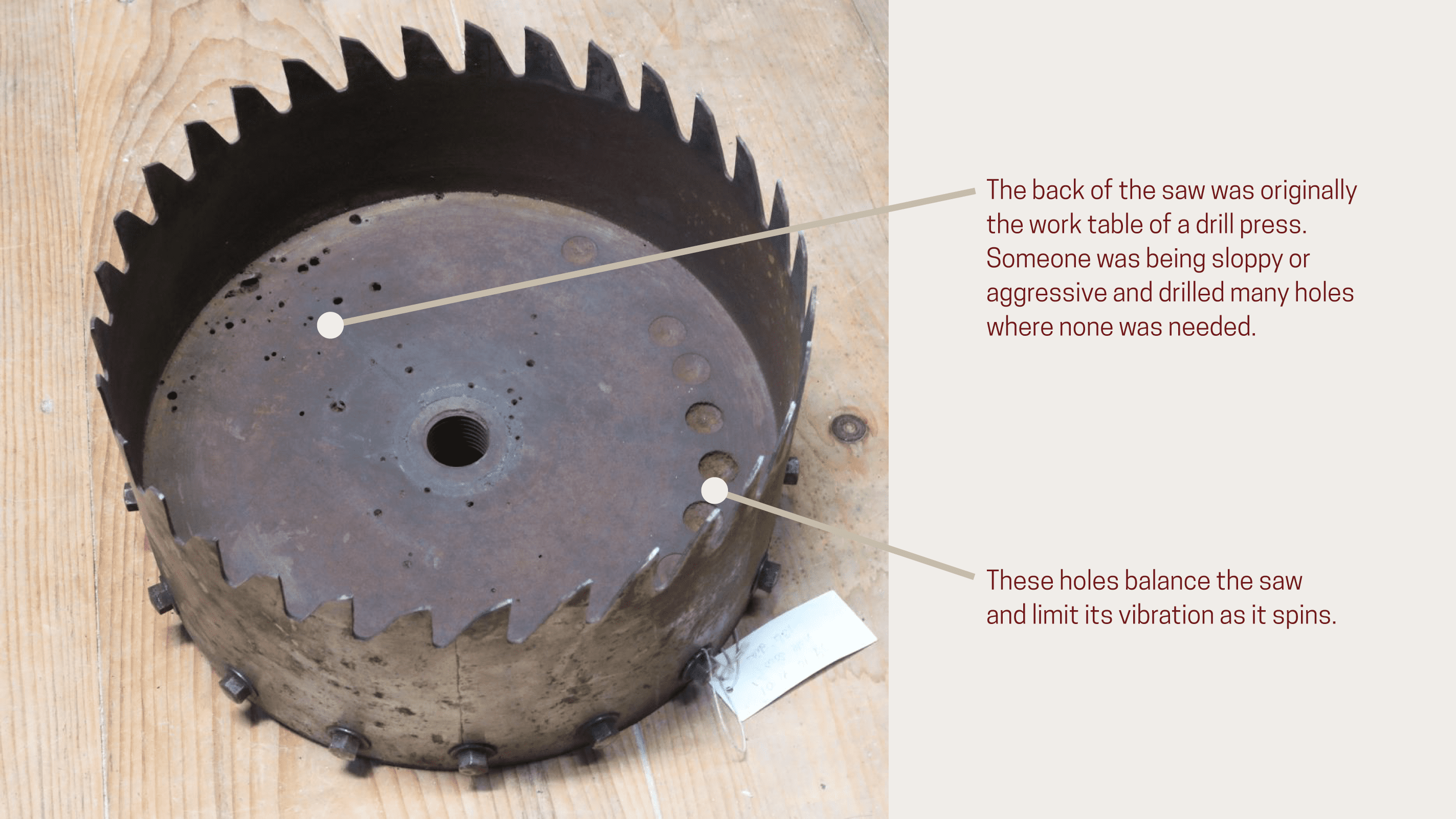

The saw is a remarkable tool. On the inside back of the saw, you can see 7 large-diameter shallow holes. These holes balance the saw and limit its vibration as it spins. But there are also 50 deeper and much smaller-diameter holes. We see that the piece of cast iron that forms the back of the saw was originally the work table of a drill press. Someone was being sloppy or aggressive and drilled many holes where none was needed.

The thin ring of hardened steel that forms the cutting surface is very neatly formed into a circle. The two ends of the metal were ground to a taper, overlapped, riveted, and brazed together, and then ground smooth again to an even thickness. This took some skill!

Some dimensions might be of interest:

The teeth are about 1 ½” long

The inside depth is 5 1/2”

The overall measure of the side is 7”.

One interesting touch is that the bolts that hold it together have a combination hex and round head. They almost seem ornamental.

I assume this was done so that if someone touched the bolts when the saw was in motion, they would not be so likely to be harmed. Not every company that did rough work, like making barrels, cared so for their employees.

Here’s a mystery about the saw. The outside surface of it is in such excellent shape, aside from some relatively spotty rust. The surface of a tool like this gets messy with use. The teeth get blunted, juices from the wood stick to the teeth, and so on. Even with maintenance, cutting tools like this do not look very good after much use. The inside of the saw does show use: the teeth have “stuff” from the material that it was cutting still on their surface. That means there must have been the same thing on the outside of the teeth, but there’s none now.

Someone sanded away the rust and stickum after the saw was no longer being used. But there’s no substantial amount of rust around the bolts, so the bolts had to be removed to clean the surface there. It’s presumable that the bolts were removed one by one, the sanding done, and the bolts replaced one by one. Whyever this was done, it wasn’t to increase production. It was almost certainly to show off the saw. Could it have been done here at the Museum? I don’t know. Priorities and personalities were very different here in APM’s early days.

Let me offer a little more about barrels. Here’s a photo of a barrel head. At 17” in diameter, it’s significantly larger than our saw would have made. Still, it would have been cut by basically the same process. It comes to an edge that fits into a groove in the barrel that holds it in place. The stenciled printing on the disc says: “Standard Sugar Refinery Boston” around the circular edge. “Purity Guaranteed Extra Fine Granulated” is above the eagle pictograph. “Eagle Brand Pure Cane” below the eagle. And the bottom text likely says, “Sold by The A.S.R.Co., Boston, Mass.” This refers to the American Sugar Refining Company which became Domino Sugar in 1900.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!