Blog

Machine of the Month: Rudy’s Own Bridgeport

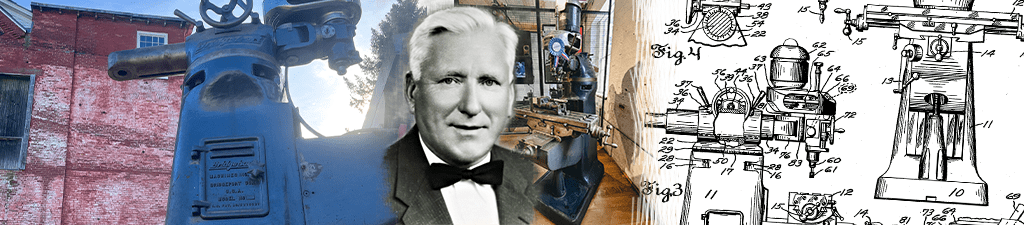

Rudolph Fredrick Bannow (1897-1962) left Sweden for the United States when he was 13 to join his family in Massachusetts. He completed his grammar school education in Holyoke and then went to work as an apprentice patternmaker. He became foreman of the Bridgeport Pattern & Model Works in Bridgeport, Connecticut, at 23. In 1927, he bought the works, using his savings and a loan of $3,000 from his mother. Rudy partnered with Magnus Wahlstrom, a fellow Swede, in 1929, forming Bridgeport Machines Inc., and introduced the Bridgeport highspeed milling attachment, which sold well despite the Great Depression.

Rudolph Fredrick Bannow (1897-1962) left Sweden for the United States when he was 13 to join his family in Massachusetts. He completed his grammar school education in Holyoke and then went to work as an apprentice patternmaker. He became foreman of the Bridgeport Pattern & Model Works in Bridgeport, Connecticut, at 23. In 1927, he bought the works, using his savings and a loan of $3,000 from his mother. Rudy partnered with Magnus Wahlstrom, a fellow Swede, in 1929, forming Bridgeport Machines Inc., and introduced the Bridgeport highspeed milling attachment, which sold well despite the Great Depression.In 1936, while delivering a pattern, Bannow got the idea for a machine built around the head the firm was producing. While sitting in his truck, he sketched the Bridgeport turret milling machine on a paper bag. The first Bridgeport mill was shipped in 1938, and more than a quarter-million have been built. This versatile machine became the foundation of the “tool and die” business of thousands of small job shops.

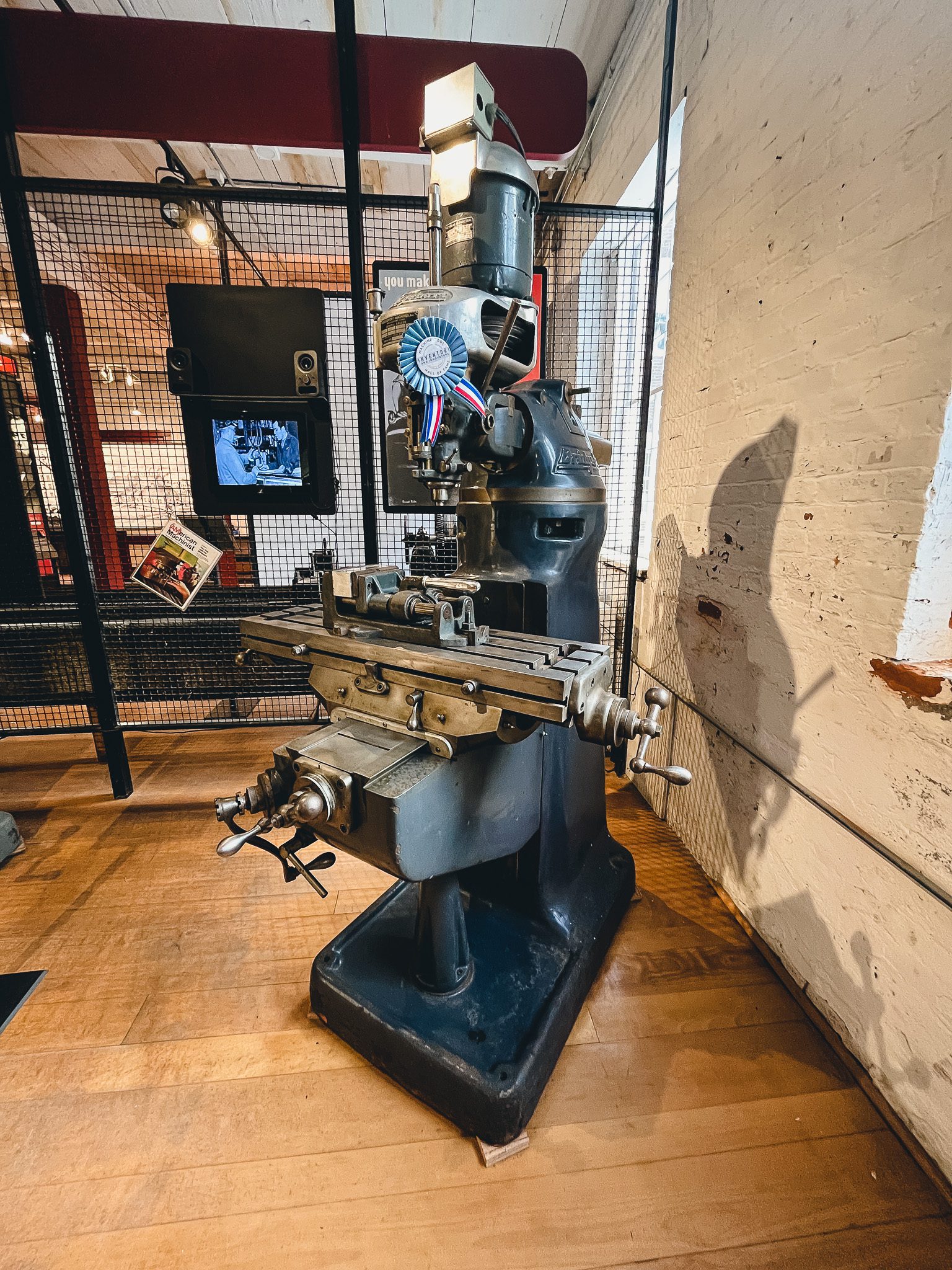

This is Rudy’s machine, which he had in his home workshop. Most of the tools that he had in his shop were for woodworking. After all, he had been a pattern maker and a professional woodworker. We are grateful and proud to present our “Newer Old Bridgeport.” It’s not much different from the Serial No. 1 from 1938. There are minor changes of various kinds, but the most striking thing about this machine is that there are no serial numbers. Where the main serial number would typically be, on top of the knee, it’s just blank.

This is Rudy’s machine, which he had in his home workshop. Most of the tools that he had in his shop were for woodworking. After all, he had been a pattern maker and a professional woodworker. We are grateful and proud to present our “Newer Old Bridgeport.” It’s not much different from the Serial No. 1 from 1938. There are minor changes of various kinds, but the most striking thing about this machine is that there are no serial numbers. Where the main serial number would typically be, on top of the knee, it’s just blank. The aluminum plate on the front of the head is stamped with the usual table of speeds; however, the serial number is also blank. Raised letters on the door indicate that patent 2,275,291 applied to this machine. That patent was granted on March 3, 1942, suggesting this machine was built around that time. The patent has to do with the machine’s approaches to cutting, which are very flexible.

The aluminum plate on the front of the head is stamped with the usual table of speeds; however, the serial number is also blank. Raised letters on the door indicate that patent 2,275,291 applied to this machine. That patent was granted on March 3, 1942, suggesting this machine was built around that time. The patent has to do with the machine’s approaches to cutting, which are very flexible.

Of course, we wonder how this came to be Rudy’s machine. Perhaps Rudy asked for a machine at the factory, and they gave him one they had on hand. Maybe it was one already working at the factory as part of the production process, but one that they felt they could part with. We will never know. It’s wonderful having these two closely linked Bridgeport machines, the high-speed head and the more modern machine, a few feet away. They can offer hints about how machine tools generally come into being and how they evolve.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact