Blog

Machine of the Month: Gilman 4-in-1 Machine

By John Alexander, Collections Technician

jalexander@americanprecision.org

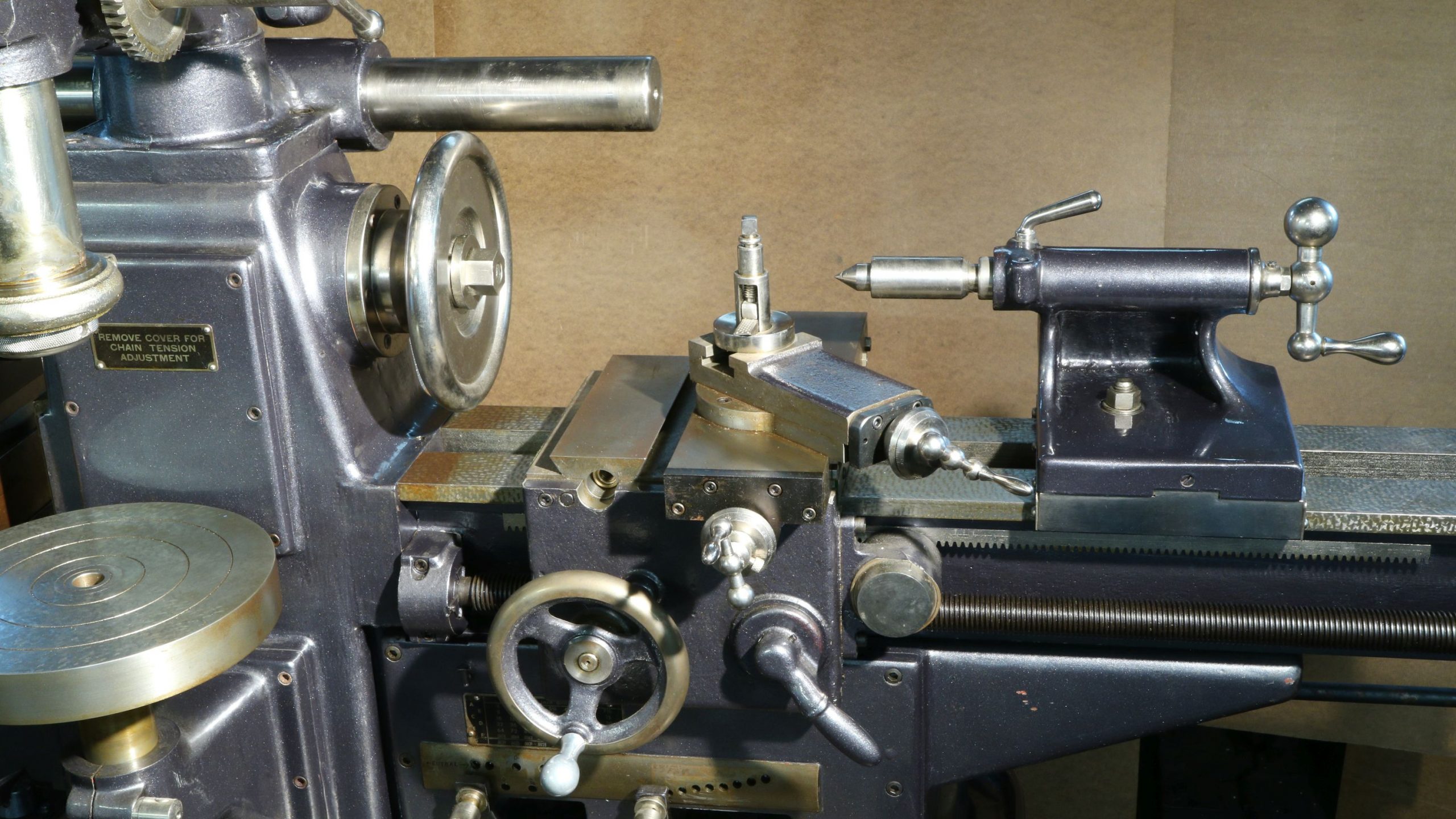

This machine is so pretty! It’s also very strong compared to the multi-function hobby machines on the market. Many who see it really want one. But according to some who know more than I, it may be the only one left in the world. How could that happen? The machine was designed for use on U.S. Navy Destroyers during World War II. Since Destroyers are relatively small ships, they couldn’t justify using much space for a machine shop. While there’s no doubt that the concept of multi-purpose machines like this was not new, this is undoubtedly a brilliant flowering of it. But after the War, the ships were eventually scrapped. It would have required lots of extra work to free up a machine, lift it up through the ship, and out onto the dock without harming it.

On the other hand, these machines lived and died in an environment defined by rank. A command structure was in charge of their whole lives. If someone with enough rank demanded it, at least one of these would have been salvaged. For many of these boats, “scrapping” didn’t mean “melting down.” Many were sunk where they could act as an artificial reef to encourage aquatic life.

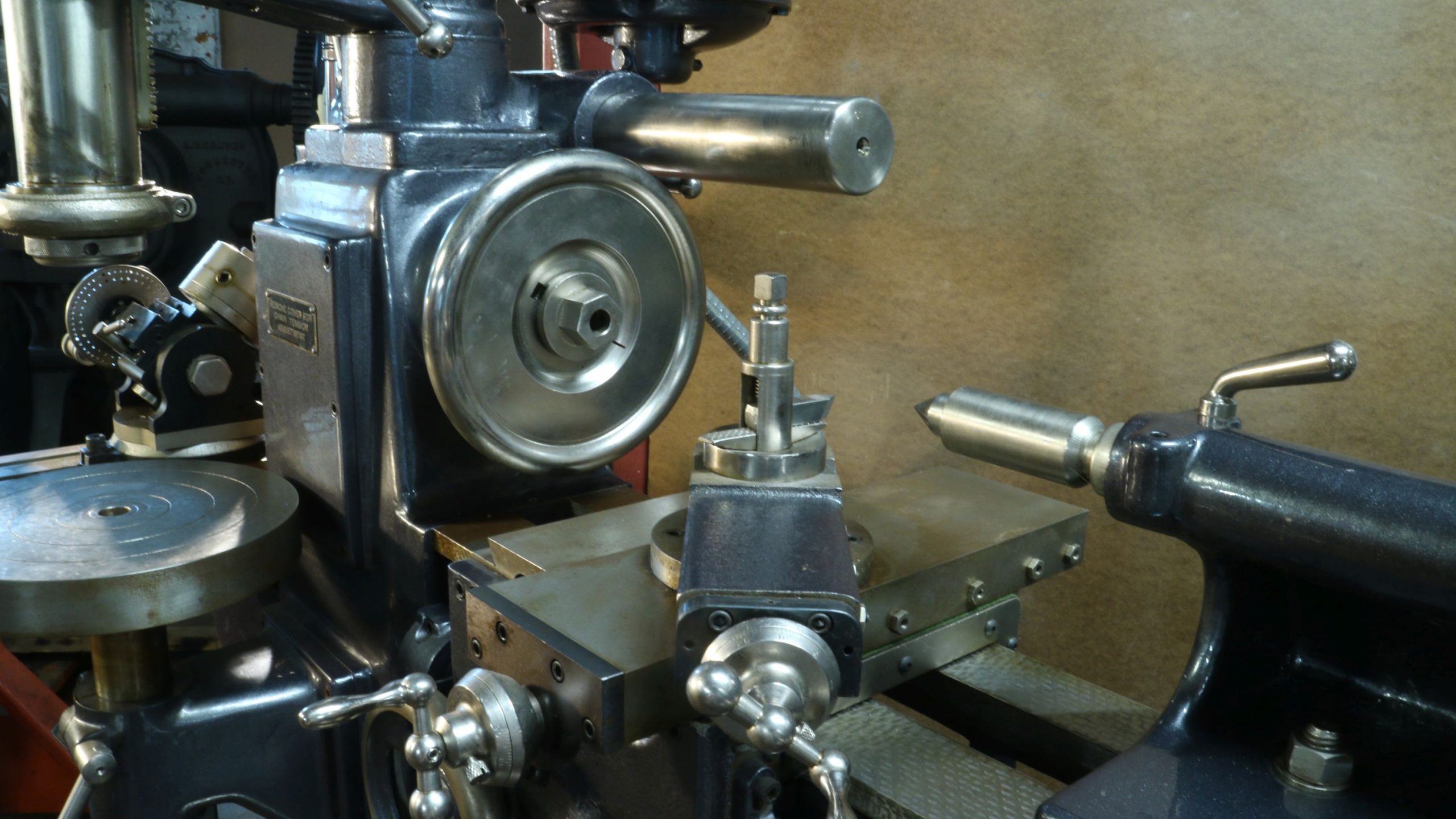

We seem to be missing a piece that would have been a table to use in place of the lathe’s cross slide and would also cover the male dovetail to the left of it. So this would be more than twice as wide as the slide now and would have T-slots to hold a workpiece. A boring bar would have been held between centers and passed through the workpiece to smooth out and true up an interior sliding surface. (Just for instance.) Note that the ways are square, not v-ridged. That is relatively unusual in the U.S.

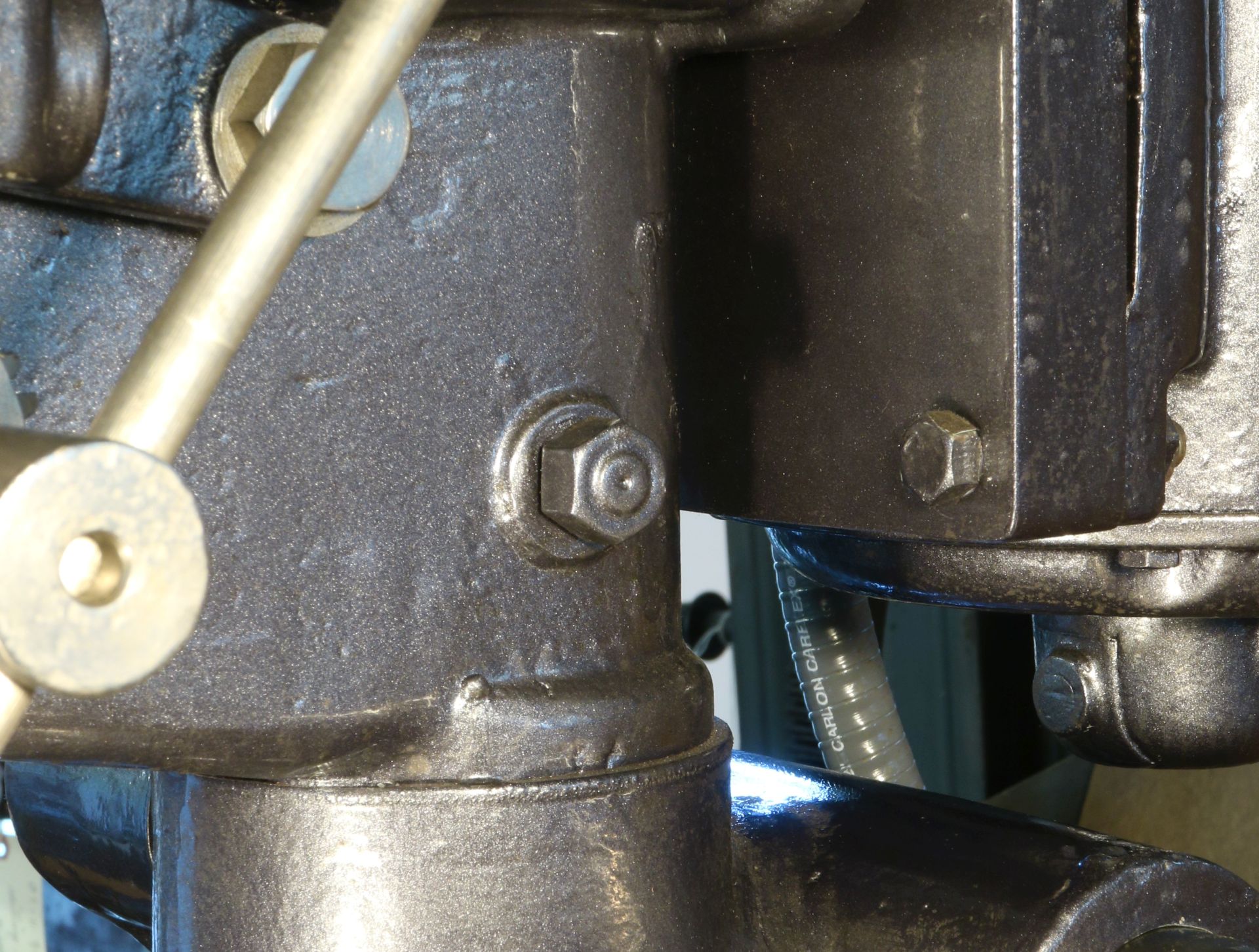

There is a nut and bolt (they are in the center of this photo) that might have been designed to grip the drill/mill’s column and release it when turning the drill head over the milling table was needed. I want to loosen the bolt and see what I could get going, but the nut, its surroundings, and most of the rest of the machine are painted in a very good-looking metal-flake gray, which I couldn’t match. (By the way, the mill/drill motor is one-half horsepower.) The collet fixture on the left end of the main spindle has a larger inside diameter than the vertical spindle.

A smooth, bright disc surrounds the main spindle’s right end. It seems to be a collet closer. Generically, ones of this style are called “speed collet” devices. If it did manage collets, it would have been a slippery proposition sometimes with that shiny finish. If it did operate collets, they would not be able to grip objects much more than about five-eighths of an inch in diameter. It also doesn’t have a hole all the way through the spindle, so one couldn’t work on a long object unless it could stick out in the direction of the tailstock.

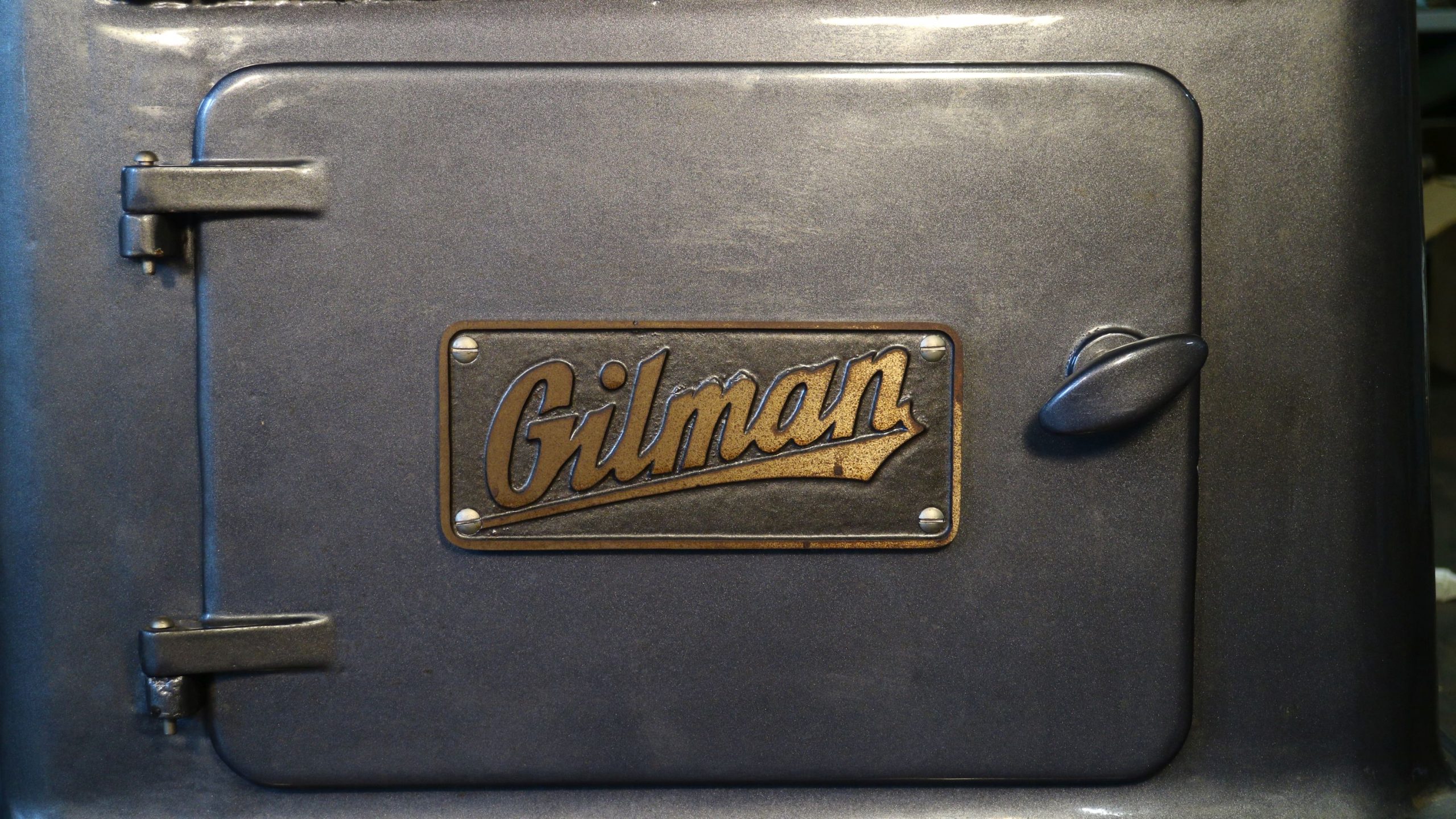

We thank lathes.co.uk for the information and, of course, Russell T. Gilman (successor to Gilman Engineering Works, who built the machine) for the machine itself. Visitors look at the machine and often ask, “What’s inside the door?” The answer is disappointing. There’s a 1 hp motor in there. It is big and fat because electrical insulation was so much thicker back then. There is room for storage inside and what seem to be cast-in shelf brackets, but there’s no shelving or boxes now. It would have been so nice if it had come with specialized hand tools or cutting tools that we could admire. Anyway, please, blow up the photo of the door so that it covers your monitor’s whole screen and eat your heart out.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!