Blog

Machine of the Month: Gear Shapers

By John Alexander, Collections Technician

Gear shapers are curious machines. They are straightforward in operation, but people often misunderstand because it’s hard to explain clearly. I hope this can help.

The primary cutting of the gear teeth is done by a cutter with teeth the same shape and size as the desired cut. The cutter approaches the workpiece while jogging up and down. Both the cutter and the workpiece are turning slowly, synchronizing with each other. After the cutter has reached the full depth of the cut, the cutter and workpiece continue turning until the work is finished. Usually, the machine will make a finish cut (or two) by moving the cutter in just a little bit and going around once or twice more.

Depending on the material of the workpiece and its size, the speed of getting to the full depth of the cut, the speed of the cutting stroke, and the rate of synchronized rotation may be changed. Gear shapers can cut precise internal toothed gears. When they were first on the scene, they were the only machine that could do that at a reasonable “production” rate. We don’t often meet with gears with their teeth pointing inward in our everyday lives, but they can be a big help to machine designers. They were an essential part of the transmissions of early autos, and are still found in crank-type pencil sharpeners.

Jones & Lamson was born around 1869. Their name then was Jones, Lamson & Company (just across the brook from where the museum is now). The name changed in 1876. The company was a descendant of Robbins & Lawrence, who had built the museum’s building in 1846. R&L was considered the best shop in the world for a while, but it went out of business in 1856. J&L moved from Windsor, VT, to Springfield, VT, in 1888. Shortly after moving to Springfield, J&L hired James Hartness as supervisor.

In 1889, Hartness was joined at J&L by Edwin Fellows. They had met years before in Torrington, CT. Fellows’ father, the principal of Torrington High School, died young. Fellows was forced to drop out of high school and work in a department store as a clothing salesman. His mother took in boarders, one of whom was Hartness. Hartness saw potential in Fellows and encouraged him to study for a career in manufacturing. When Hartness had established himself as head of J&L, Fellows went to work for him. His first job was as a machine operator; his second was in the drafting department. Here, he studied the ideal tooth shapes of different types of gears. He realized he could design a machine that could cut more profiles and cut them better than machines already in use. Hartness approved of his inventing, but he wanted J&L to build only the flat turret lathe he had designed. He encouraged Fellows to start his own firm. Fellows got backing from several Springfield industrialists (including Hartness) and founded his company in July 1896.

The first gear shaper, a 36” diameter capacity machine, was built in Fitchburg, MA, in 1896 before the first tiny shop was even finished in Springfield. The machine was “experimental” and was never sold.

Our museum had an early machine of that size that looked a lot like those early ones. It was on loan to us from the Smithsonian Institution and was returned to them in 2006. Its serial number is 145.

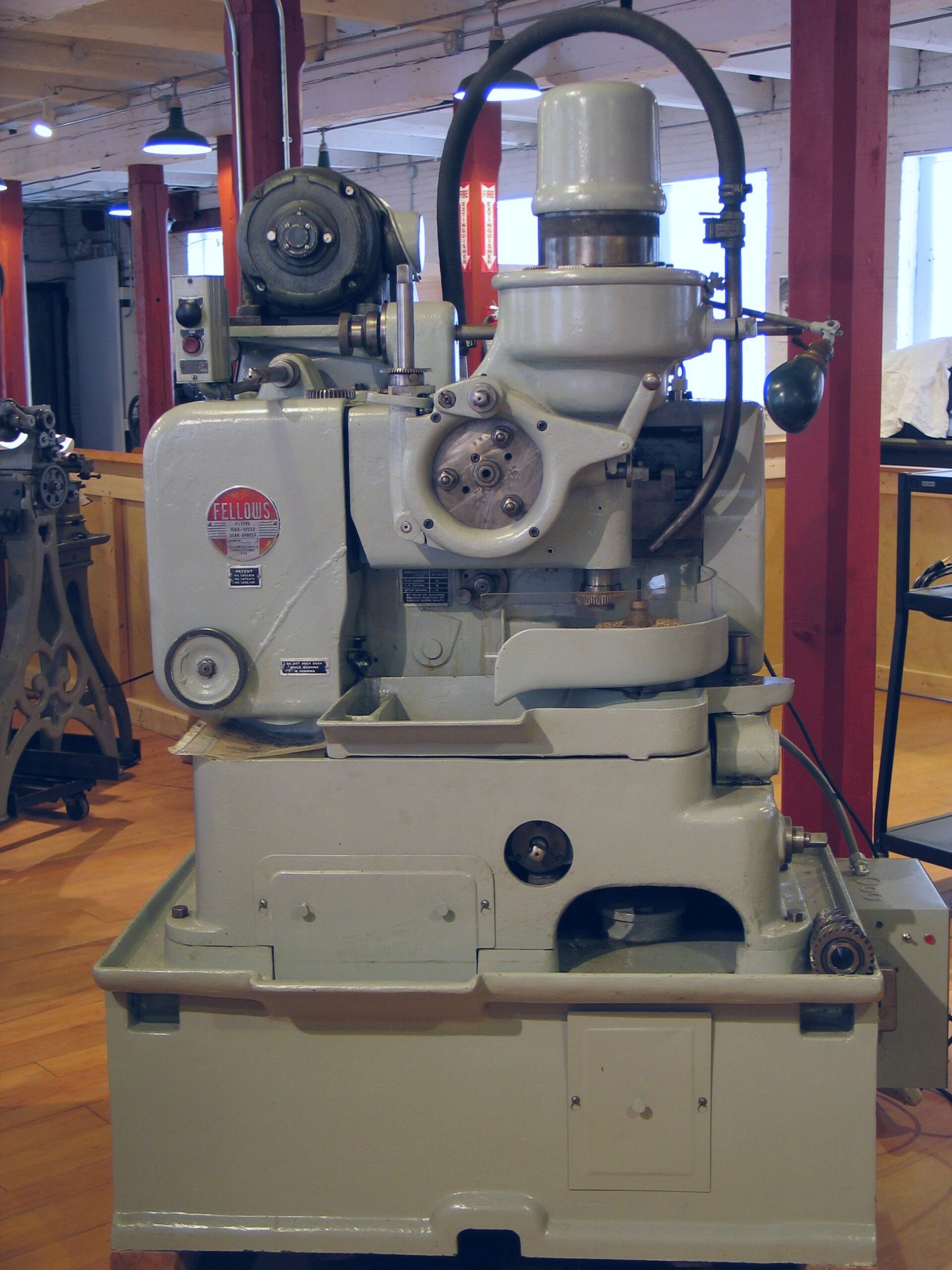

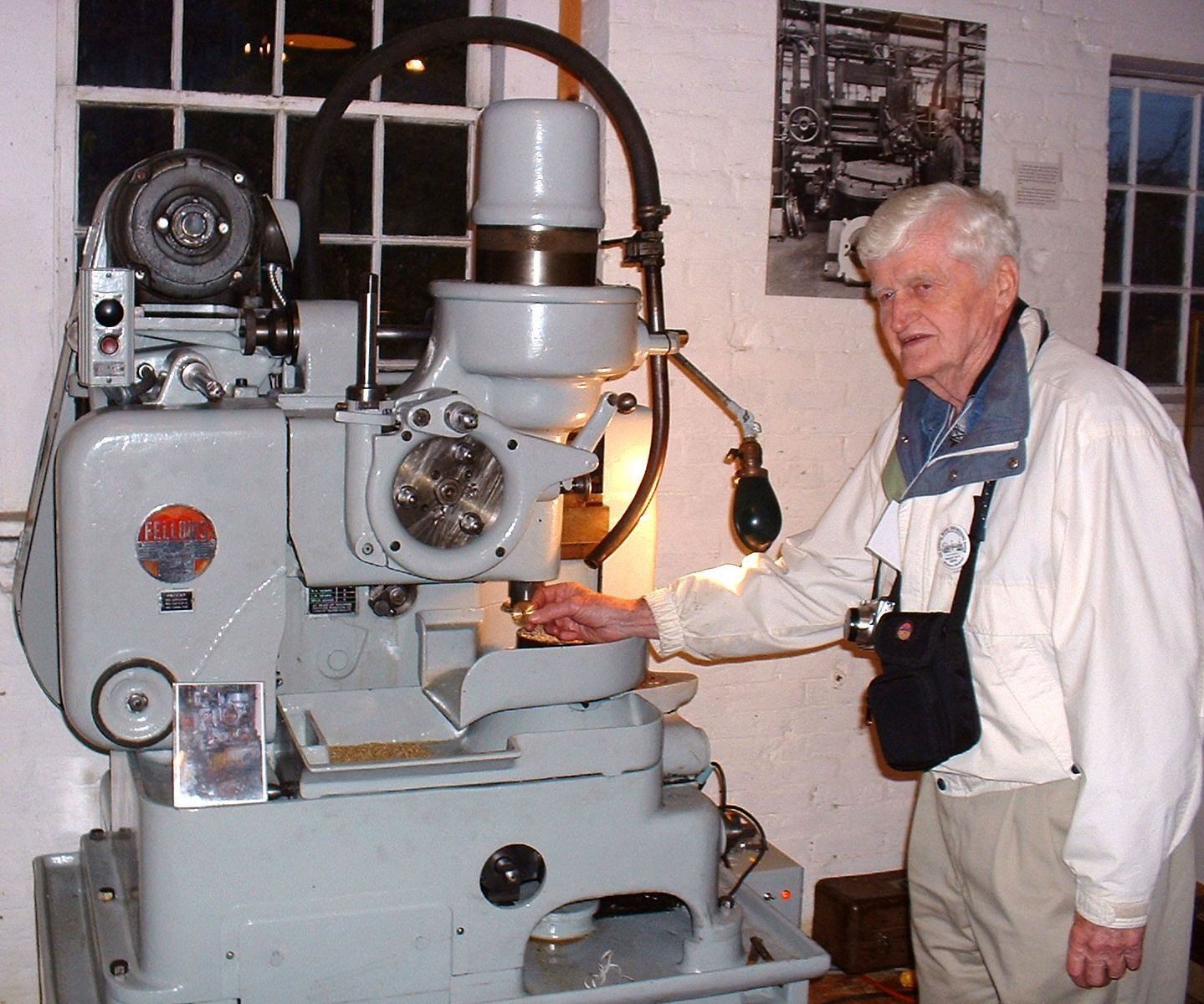

We do have what’s possibly the oldest existing gear shaper. Most of what we know about it is featured in this article from the Fellows Company Newsletter, The Pitchline. The serial numbering started at 50, so it makes sense to say, “serial #59 gear shaper was the tenth machine built”. The article mentions that it was found in 1960. It came to the museum in 1968. This shaper isn’t on exhibit, but can be seen on a behind-the-scenes tour.

Note from the author: The writer of the Pitchline article thought that our older gear shaper had been made in about 1898. Doing a bit of wriggling, I got a photo of the hidden backside of the machine in March 2024. This revealed a list of patents cast in raised characters. The date of the last two patents is 1901. Looking at an old inventory of our collection (where I should have looked before,) I found a note saying that our founder, Ed Battison, had dated the machine to “circa 1903”.

Don Whitney with his baby.

Don Whitney with his baby.It’s interesting to compare our old machine and our newer one. Leather belts drove the old machine from an overhead shaft. The newer one has a built-in motor. The old machine can cut a 24” gear, the newer one only 7”. The new machine is heavier. The old one is not nearly as strong. The advantage of the newer one is that its strength allows it to cut much faster. But, more meaningful to most jobs, it can maintain more precision in the finished product and a better finish.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact