Blog

Machine of the Month: Frederick Howe’s Horizontal Milling Machine

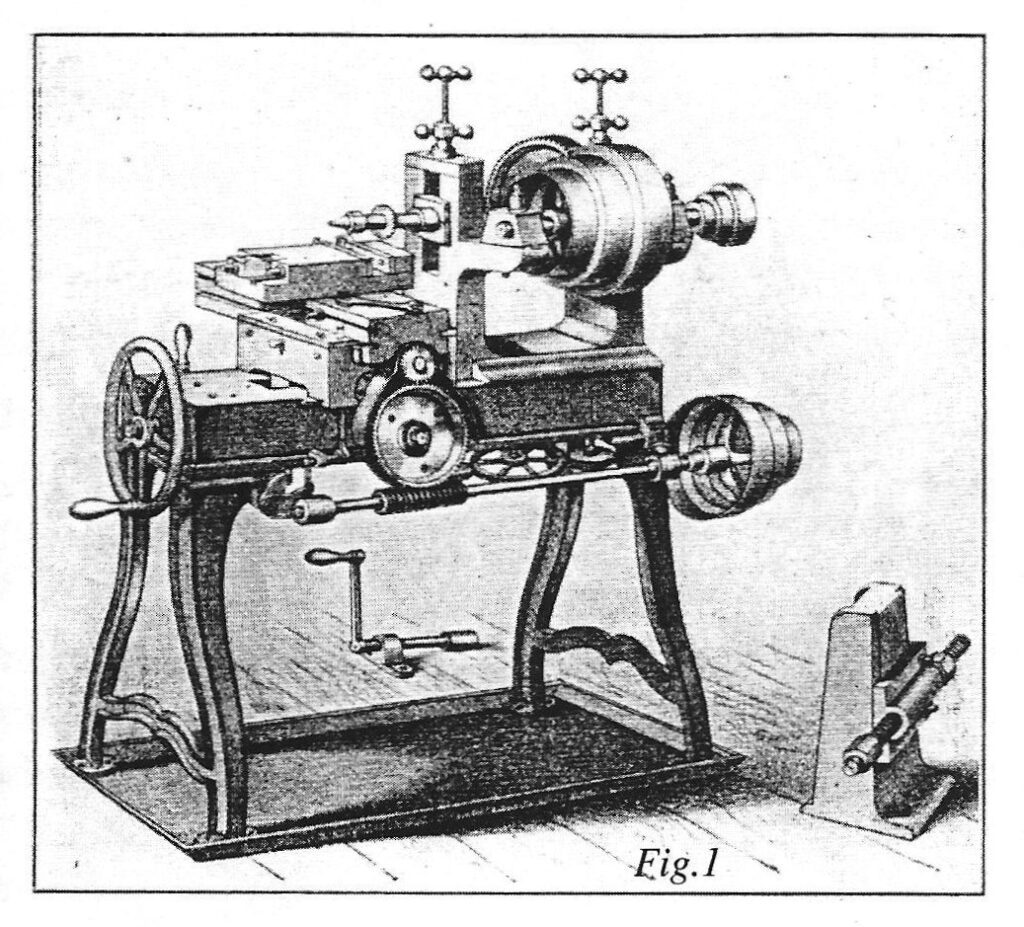

We have an old milling machine on exhibit that was made here, designed by Fredrick W. Howe, a plant manager for Robbins & Lawrence. It’s being driven by a belt powered by the overhead lineshaft. That, in turn, is powered by a crank mechanism that a visitor can operate. The machine is simple and straightforward by modern standards. What distinguished it, when it was new was that it was strong and versatile. It came into being about 1848.

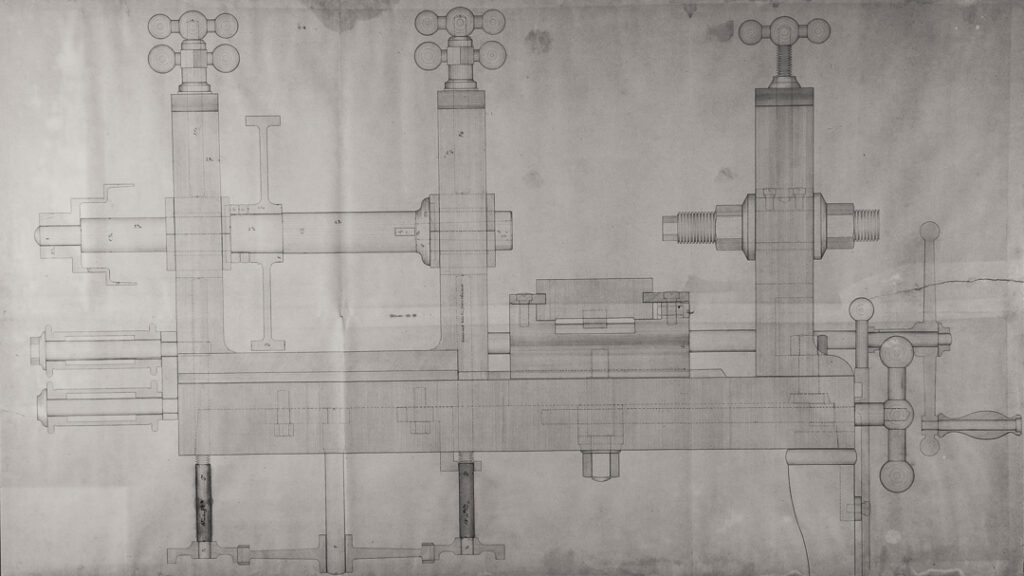

The amazing thing is that we have something like a birth certificate! We have an actual-size drawing of it, quite likely by the hand of F. W. Howe himself. It really is quite beautiful. But please note that interesting part, “actual-size drawing.” It had no dimensions when it was made; it was designed to be measured to get the correct sizes for the components! There are a few dimensions written in now, but they were mostly put there by the machinists who worked from it, not the designer. This was just before the revolution in measurement that led to interchangeable parts. That also led to blueprints and other technical drawings as we know them today. Displayed on the wall behind the mill is an enlargement of part of the original drawing. It’s been worked on by a graphic designer. The original isn’t on display now.

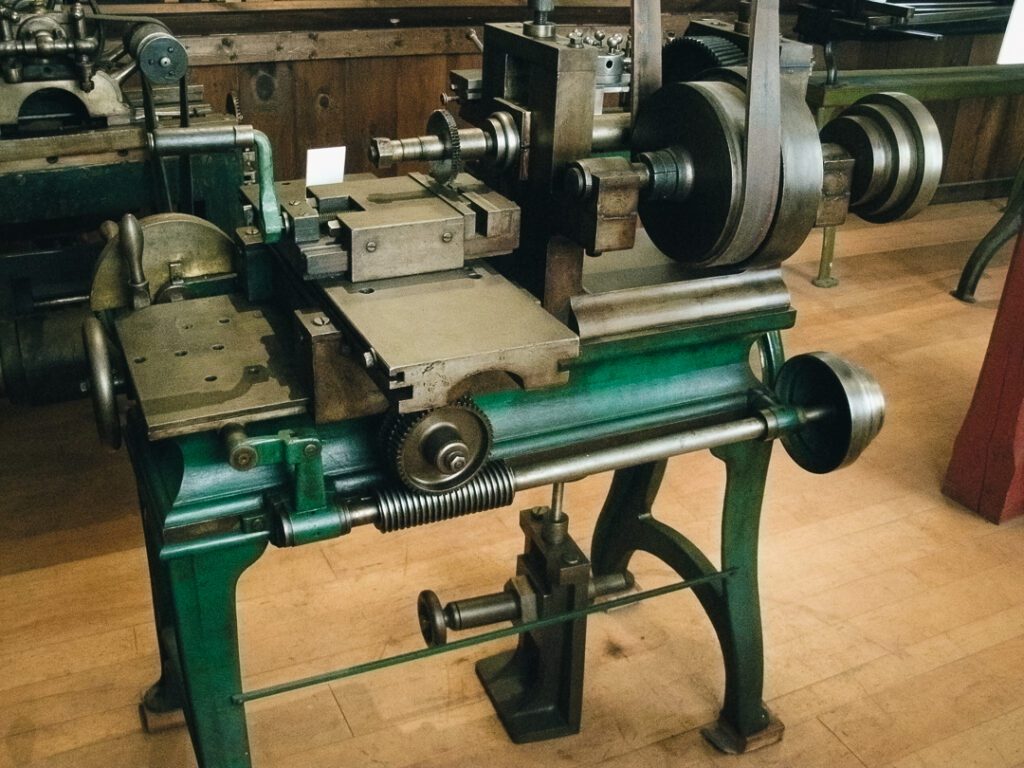

In the Howe design, the table moves under the work driven by a rack and pinion. A rack and pinion is composed of a straight gear (the rack) mated with a round gear (the pinion). This system has the disadvantage that as the gears move from one gear tooth to the next, there is a slight bump. In some situations, the bump is magnified and makes a mess of the work, breaks the teeth of the cutter, or even harms the machine. In 1854, Francis Pratt worked for George S. Lincoln in his Phoenix Iron Works. Pratt made an important change in Howe’s miller. Instead of having a rack and pinion, Pratt used a threaded rod on the body of the mill and a nut attached to the table. This gave a more reliably smooth cut, and the milling machine was less expensive to manufacture. Since the machine was first produced by the Phoenix Iron Works, it became known as the Lincoln mill.

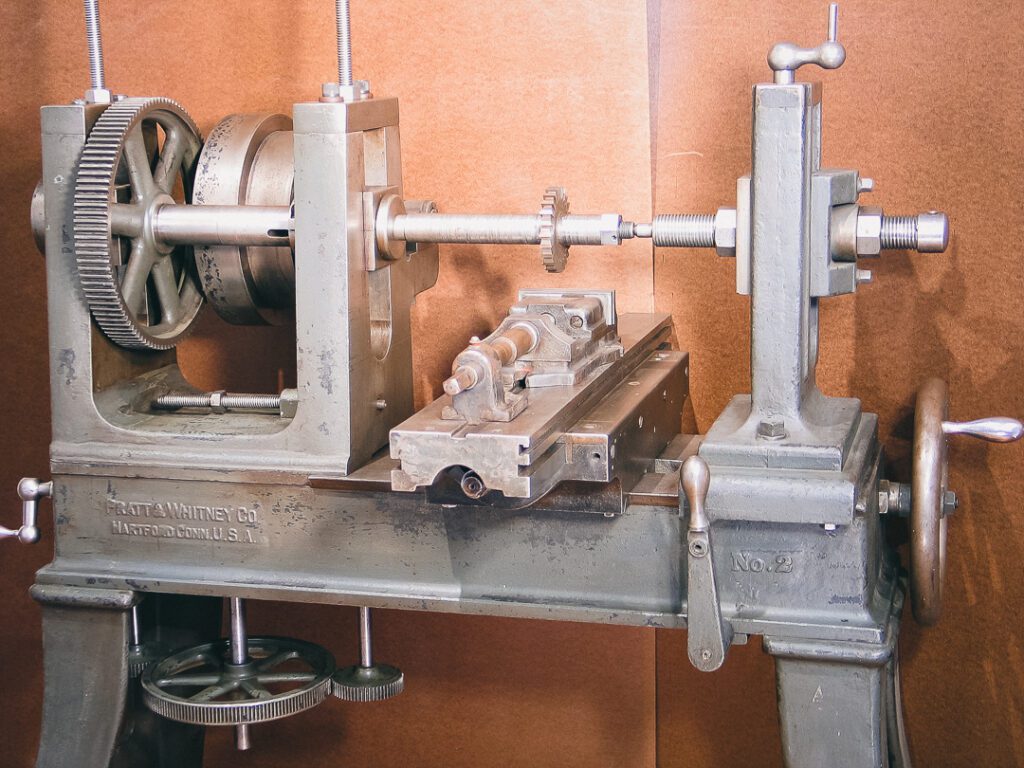

Pratt’s simple but beneficial change made a machine that was produced well into the 20th century, and we have one of those too! This one was made by Pratt & Whitney. That’s the machine tool company that Francis Pratt and Amos Whitney co-founded in 1860. It’s not on display now.

This “founding drawing” and group of three succeeding machines is unique in our collection. If you’d like to see the original drawing and the machines that aren’t on display, please book a Behind the Scenes Tour of our collection.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact