Blog

Machine of the Month: First Model Jones & Lamson Flat Turret Lathe

This all starts way back, and it starts here!

This all starts way back, and it starts here!

After the Civil War (1865) American Precision Museum’s building became a cotton mill. It and the machine-making shops across Mill Brook became Jones, Lamson & Company. In 1876, the machine works became Jones & Lamson, and the cotton mill kept its name. The cotton mill machines were sold in 1886; since then, our building has not been used for manufacturing.

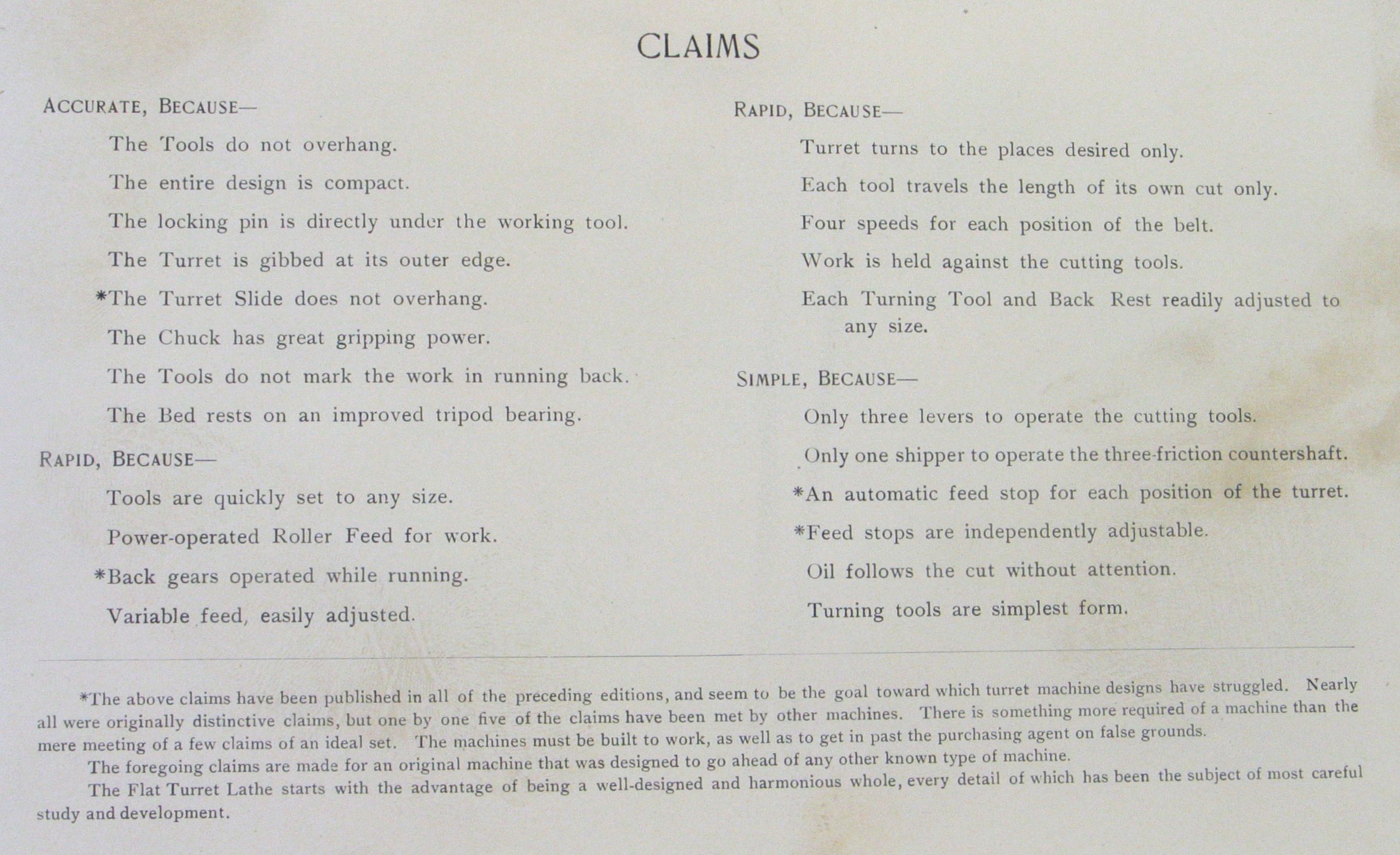

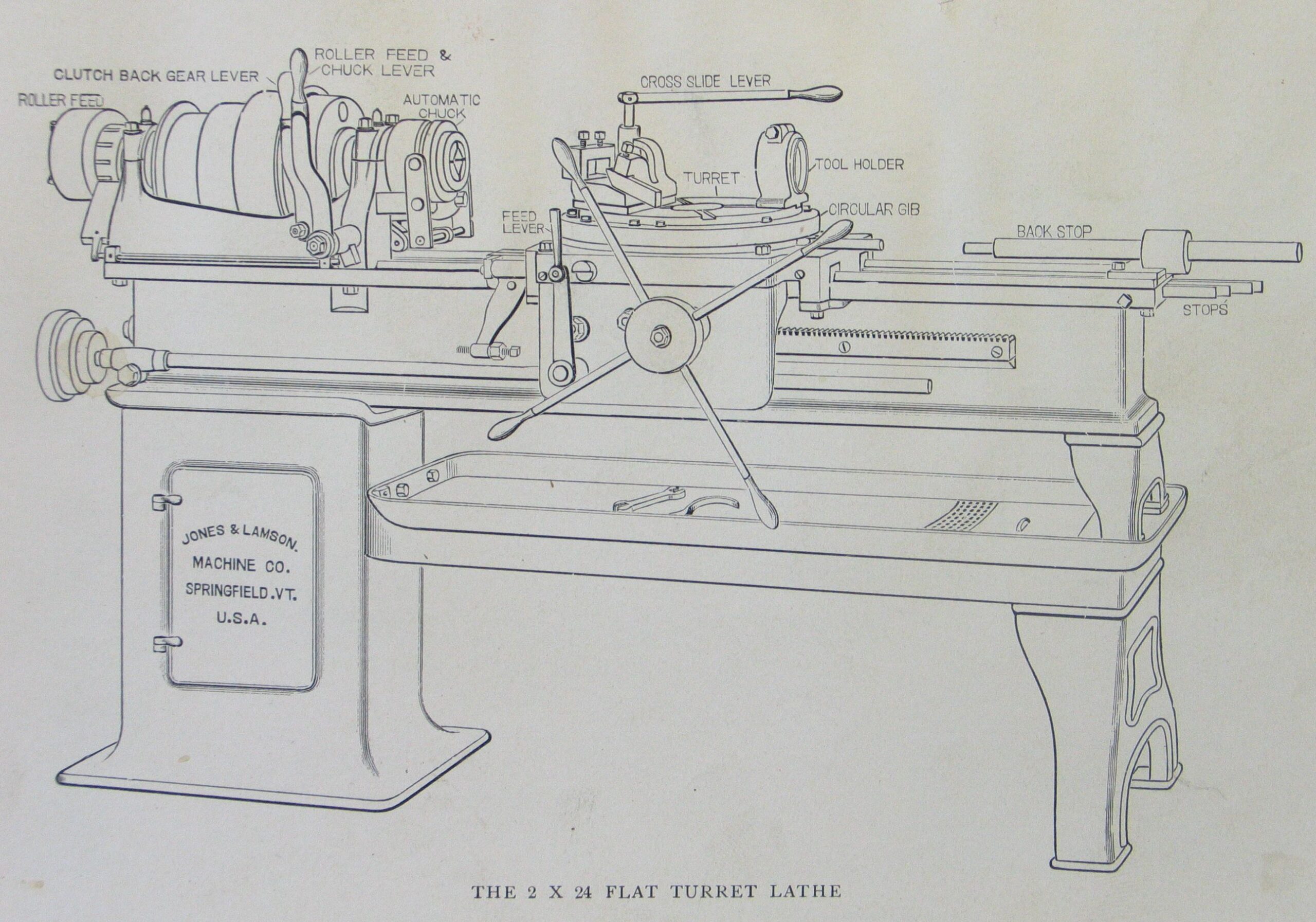

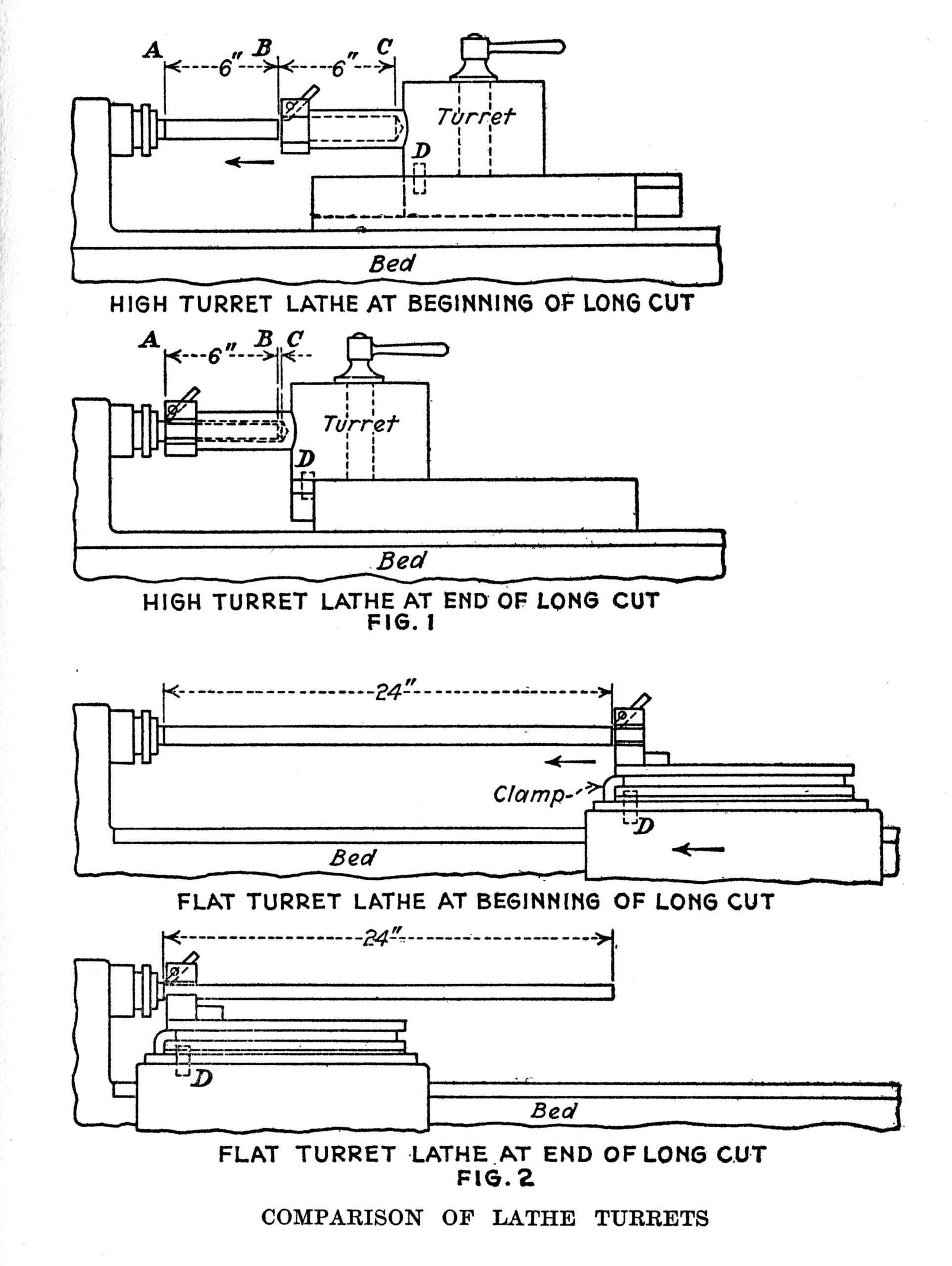

In 1888, Jones & Lamson moved to Springfield, Vermont. James Hartness (1861 – 1934) was hired as superintendent. His first day with the company was April 1, 1889. Clearly, Hartness had permission to make changes as he saw fit. He had been designing a new kind of turret lathe even before coming to J&L. In the traditional style of turret lathe, a cylindrical turret rose above the slide that carried it. The tools were mounted in holes bored into the side of the turret. The workpiece couldn’t extend into the turret. The patent for the flat turret lathe was applied for in January and granted in August of that year.

In Roe’s biography of Hartness, he describes it this way: “The short time taken for the application to go through the patent office is an indication of its character. In the patent office jargon, there was almost no ‘prior art’ in its line.” In Hartness’ new design, the turret was a low-lying disc attached to a carriage, similar to an engine lathe, and the tool holders were bolted to its surface. There are significant advantages to this system. The workpiece can extend out above the surface of the turret. If a threaded part is needed, the thread can be longer than the turret is wide. There is a lot of room between each tool station and the next on the turret. If the setup person wants to use complicated tool holders with slides and so forth, there is space to do that. Because the turret is 16” across, much wider than a comparable traditional turret, and has a more strategically placed locking mechanism, it is very rigid when cutting. Here are three pages from a J&L catalog/brochure that explain the difference.

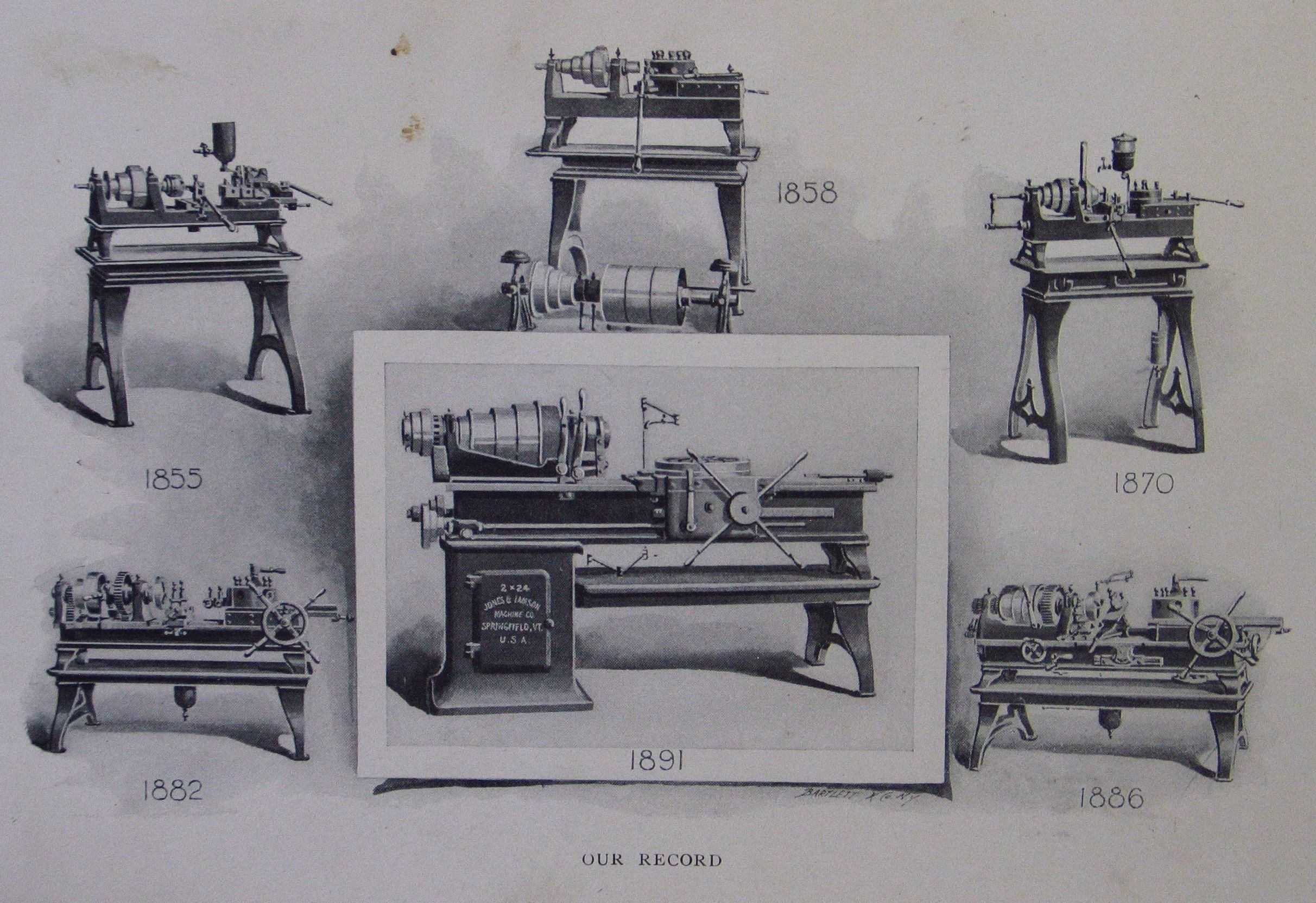

The Flat Turret Lathe was first sold in 1891 and proved a good seller. A substantial article in American Machinist Magazine in May of 1891 cited its clear advantages. For nearly a decade, J&L sold only this one machine in this one size. That’s right; it was their only product!

Starting in 1903, a more powerful version of the lathe was sold. It was much heavier than the original lathe in its smaller versions. APM’s collection includes one whose maximum workpiece diameter is 3” and its length is 30”. That machine is an absolute monster, at least twice the weight of our Machine of the Month. There are a number of design differences between the lathes, but the most remarkable is that on the latter one, the whole head shifts to the side to do a facing operation. That head contains a lot of metal, maybe as much as 500 lbs., a quarter ton! Even though it has a power feed, it would be a tough machine to operate all day.

Restoration work started on our early flat turret lathe in December 2003. It has been on display since May 2004. The restoration was done by Mike Riviezzo with substantial help from Pam Levesque and Clay Washburn.

Here’s another little treat for you. The advertising catalog/brochure of about 96 pages had an embossed paper cover. It must have been very pretty in its day.

Read More about Jones & Lamson and their factory in Springfield

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

This all starts way back, and it starts here!

This all starts way back, and it starts here!