Blog

Machine of the Month: Bryant Chucking Grinder Model 10 A

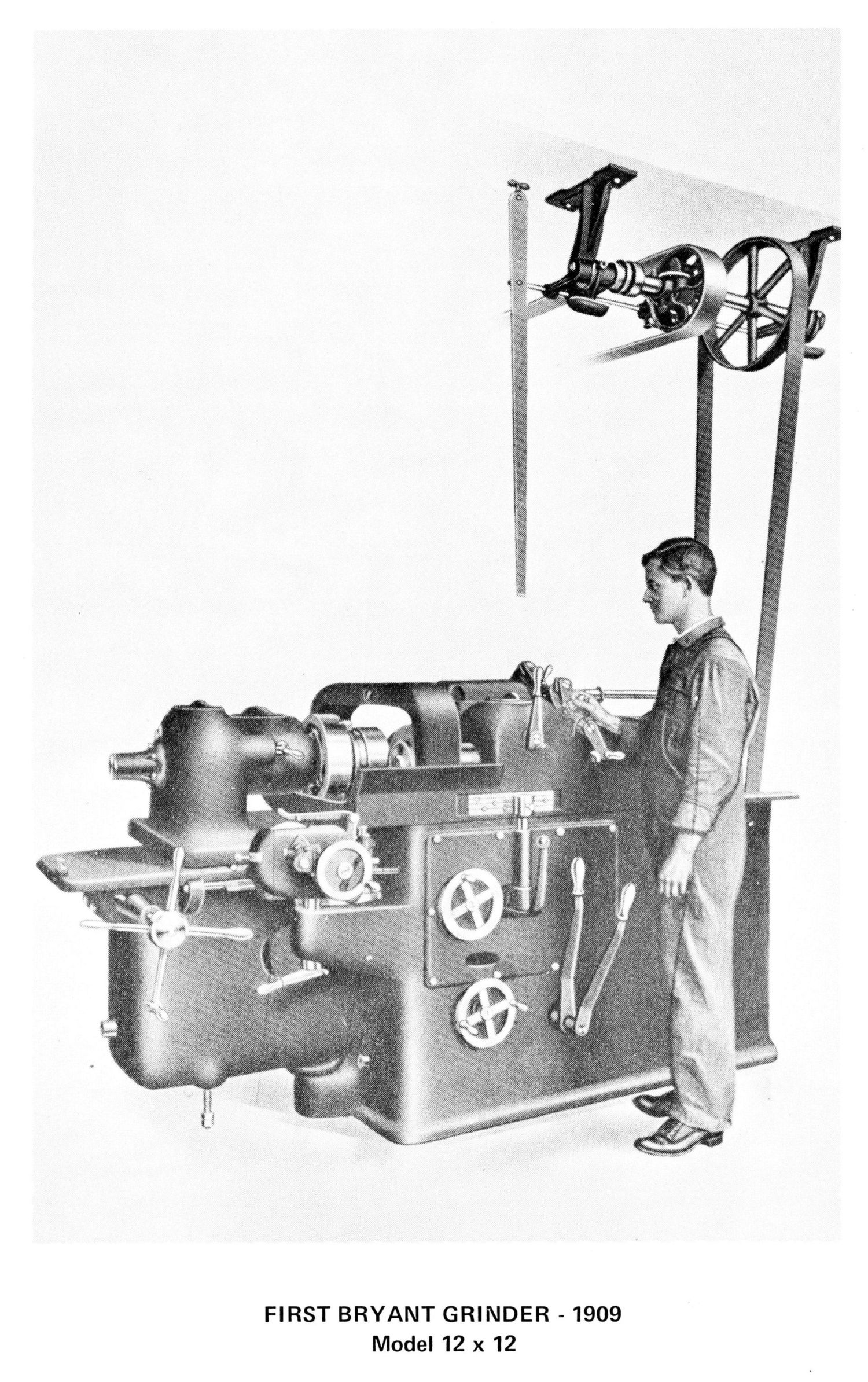

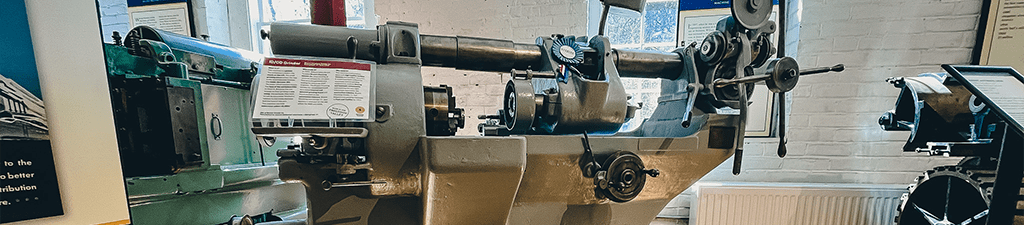

The Machine of the Month is Model Number 10 A, manufactured by Bryant Chucking Grinder of Springfield, VT.

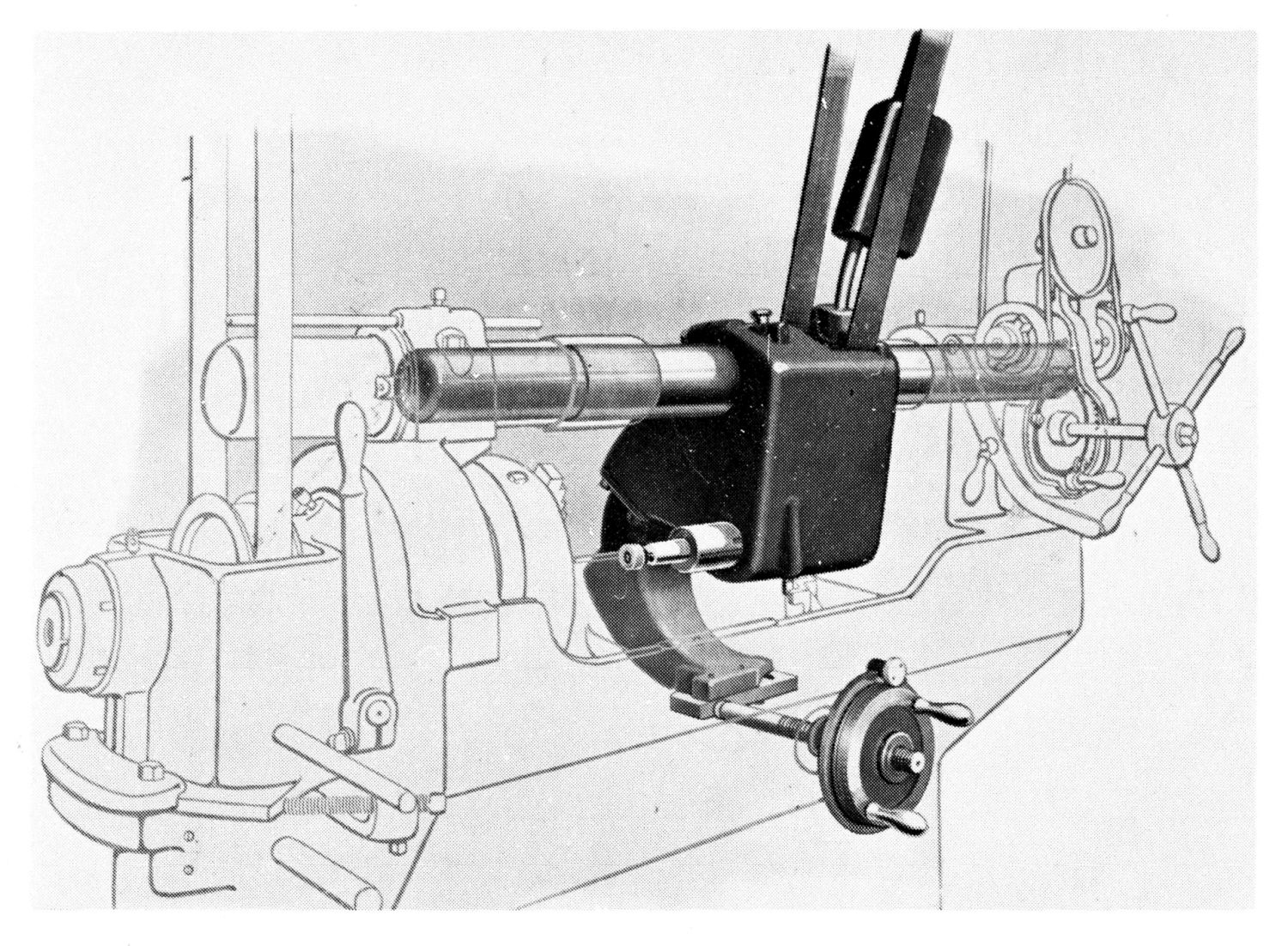

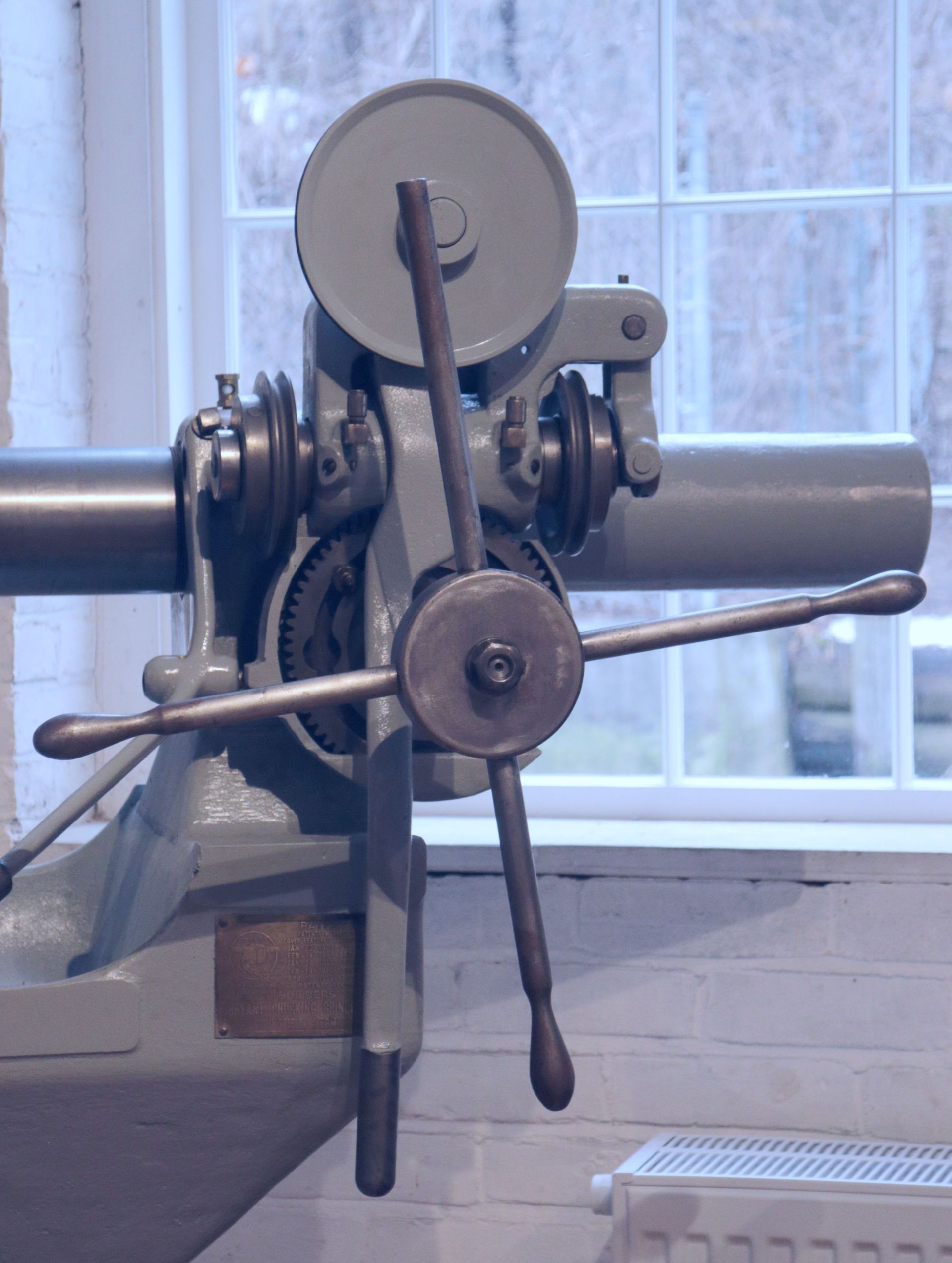

The Number 10 A introduced a unique method of moving the grinding wheels in relation to the workpiece. It was called the “Three Point Suspension” system, and it was used by Bryant at least into the 1970s. Instead of having conventional ways below to slide on, it has an overhead cylindrical bar on which the grinding spindles are moved back and forth (to the operator’s left and right) and swing from side to side (away from and toward the operator).

To change the diameter of the hole in the work, the head would swing away from the operator, controlled by turning the handwheel at about hip level with two handles.

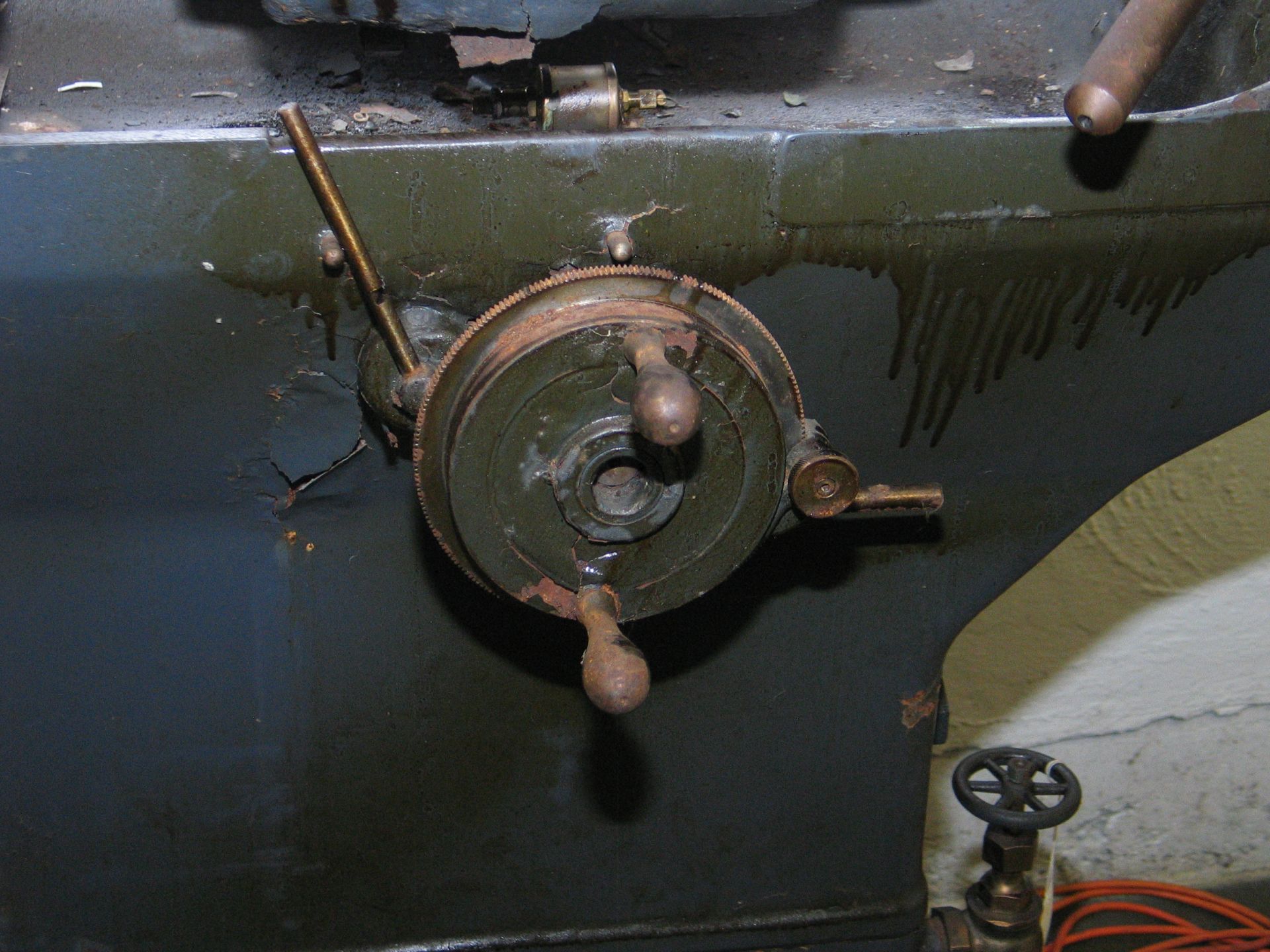

Our Number 10 A was built in about 1920. It was given to the Museum in 1986. Unfortunately, it was stored in our basement, a very high-humidity environment. In December 2010, APM moved all the machinery in the basement to a local factory building with much better conditions. After being stored on the park’s plaza overnight, the machines were lifted over the office area (!!) and lowered onto a truck. Then they were moved across town to excellent, low-humidity storage.

About 2016, our 10 A was “adopted” by Don Whitney for restoration. Don had previously led the team that restored the Fellows 7-Type Gear Shaper that now works cutting gears in our Innovation Station. He had some significant help working on the 10A, but for the most part, it was his baby. Restoring the grinder wasn’t fast. It had gotten deeply rusted in places, and several parts fiercely resisted removal for cleanup or replacement.

Also, Don Whitney wasn’t as strong as he’d been earlier in his life. For most of his life he had been very active in hiking and skiing. He helped maintain hiking trails for the Appalachian Trail and other local trail systems. He helped collect and organize objects from Fellows Gear Shaper Company for a historical display in Springfield. He’d been a trustee of the American Precision Museum and done other volunteer functions for us. Notably, he did research on all sorts of machine-related topics. But in 2018, when restoration work on this grinder was finished, he was 96 years old. Don lived from October 11, 1922, to March 8, 2022. We are grateful to him, and we are glad that we knew him.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact