Blog

Machine of the Month: Bridgeport Serial No. 1

The First Bridgeport

Many who read this will already be familiar with the First Bridgeport, which we proudly display. There are some features on it that aren’t widely known about that I’ll touch on. The Bridgeport was created by Rudolph Bannow (Rudy). Bannow was born in Sweden and came to the US at 13, learned the pattern maker’s trade, and later became a foreman at the Bridgeport (Conn.) Pattern and Model Works. He bought the company in 1927 and took in Magnus Wahlstrom as a partner two years later. The partnership soon produced a high-speed milling attachment, followed by a version with a quill.

In 1936, while delivering a pattern, Bannow got the idea for a machine built around the head the firm was producing. He sketched the Bridgeport turret milling machine on a paper bag while sitting in his truck. The first Bridgeport mill was shipped in 1938, and more than a quarter-million have been built. This versatile machine became the foundation of the “tool and die” business of thousands of small job shops.

There’s the serial number. It’s just a number “1” that’s stamped into the top of the knee and into both the left and right sides of the saddle, which supports the table. If you look closely at these numbers, especially under a bit of magnification, it seems likely that they weren’t made with a number punch. More probably, they were made with a small chisel, and that chisel was perhaps made from a cutting tool bit. It would have been done that way because the company apparently didn’t yet have a set of number punches that were that size. The numbers stamped on the head are much smaller; they are made with a small set of punches.

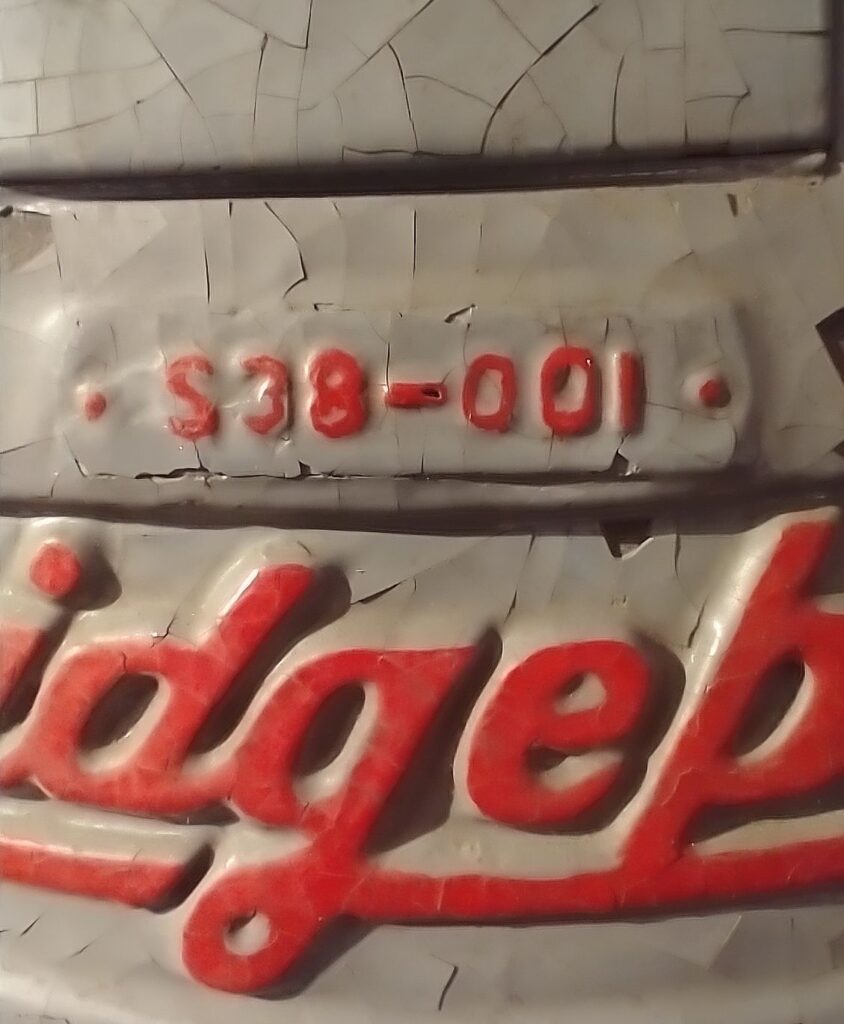

There is at least one other place where the company seems to have celebrated the machine’s status as the first of its kind. Above the company name on the right side of the machine, there’s an oval sheet metal strip, about 3 ¼” x ¾ “, with raised characters: S38-001. That “38” would be for “1938”, the year the machine was made.

That style of strip is something that foundry pattern makers often put in a pattern to identify it. It’s something that will stay legible through repeated trips through the mold-making process. I mention this because we mustn’t forget that the company was called Bridgeport Pattern & Model Works. They were still making patterns.

High-Speed Head

We haven’t given enough attention to this small device mounted on the back of the ram of the First Bridgeport. It is called, at least generically, a “high-speed head.” It is one of the earliest machines sold by the Bridgeport Pattern and Model Works.

It has the Bridgeport Pattern and Model Works name in raised letters cast into the top of the main casting. Also, the Bridgeport name is cast into the front in the same stylized form still in use for their trademark.

It’s a fairly simple machine. It has a 1/4 horsepower, 220-volt motor, directly driving a pair of v-belt pulleys with four steps to change the speed (the Bridgeports mills have five steps,) a spindle to hold the cutting tool, and a swivel with a degree circle to allow the tool to work at an angle.

On the front, there are two raised machined surfaces, “bosses,” one above the other, that can be used with a dial indicator to position the head accurately in relation to the work table. Later model Bridgeports have these too.

Although it’s called a “high speed head,” its speeds aren’t very different from those on old Bridgeport machines. It was an accessory that could be attached to a heavier, slower machine to give it versatility. A more formal name used for it was “Universal Milling Attachment.”

These heads were first sold in 1932, which was well into the Great Depression, but they did sell well. Before they were sold, Bridgeport Pattern & Model Works wasn’t in the machine business; their name described their stock in trade. Undoubtedly, the promising sales of these type “C” heads led to the development of the much more sophisticated “M” head that we see on the other end of the ram on this same mill.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!