Blog

Glazier’s Points

Things have changed so much. It used to be that all window frames were made of wood except some iron ones in industrial situations. Now, even wooden framed windows have two parallel panes with nitrogen trapped between them and complex metal and plastic sealing systems. In the time of windows being made only of wood, the usual procedure was to lay the glass in place, give it a good solid grip on the wood with glazier’s points, and then seal the edge of the glass and the points with glazier’s putty. When I first met glazier’s points, they were equilateral triangles, about 1/2” on a side. They would be pushed into place with a putty knife or perhaps a screwdriver.

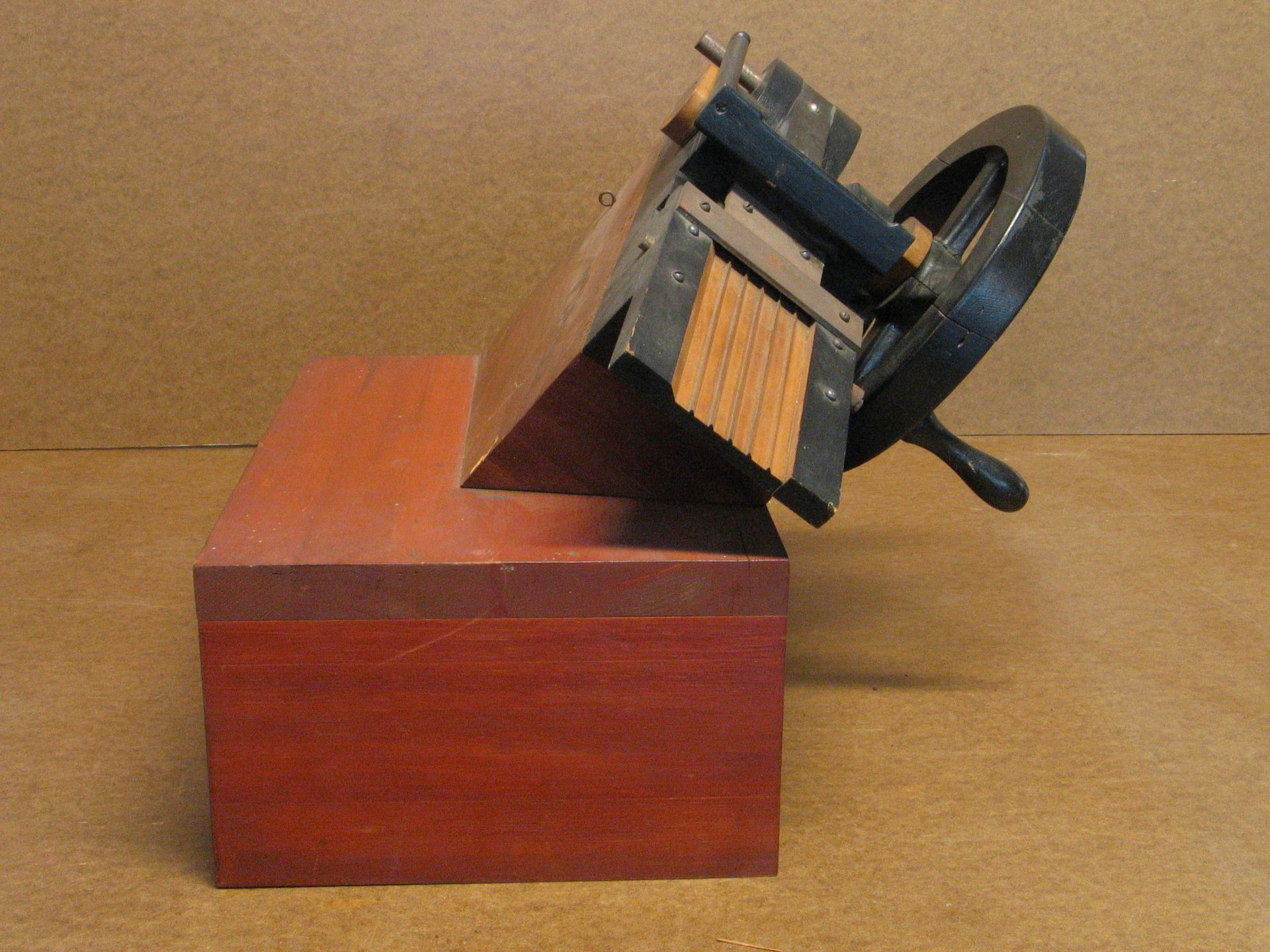

The Museum has a machine that made this style of points. The tooling that is on it allows it to cut six points at a stroke. An interesting feature is the crank handle on the flywheel. From the look of things, the shop-made, bolted-on crank was the one-and-only power source for the machine. That would mean that the shop where it was didn’t use it for large production runs. Making a batch of points may have been a task for an apprentice. This machine came to us from Upstate New York.

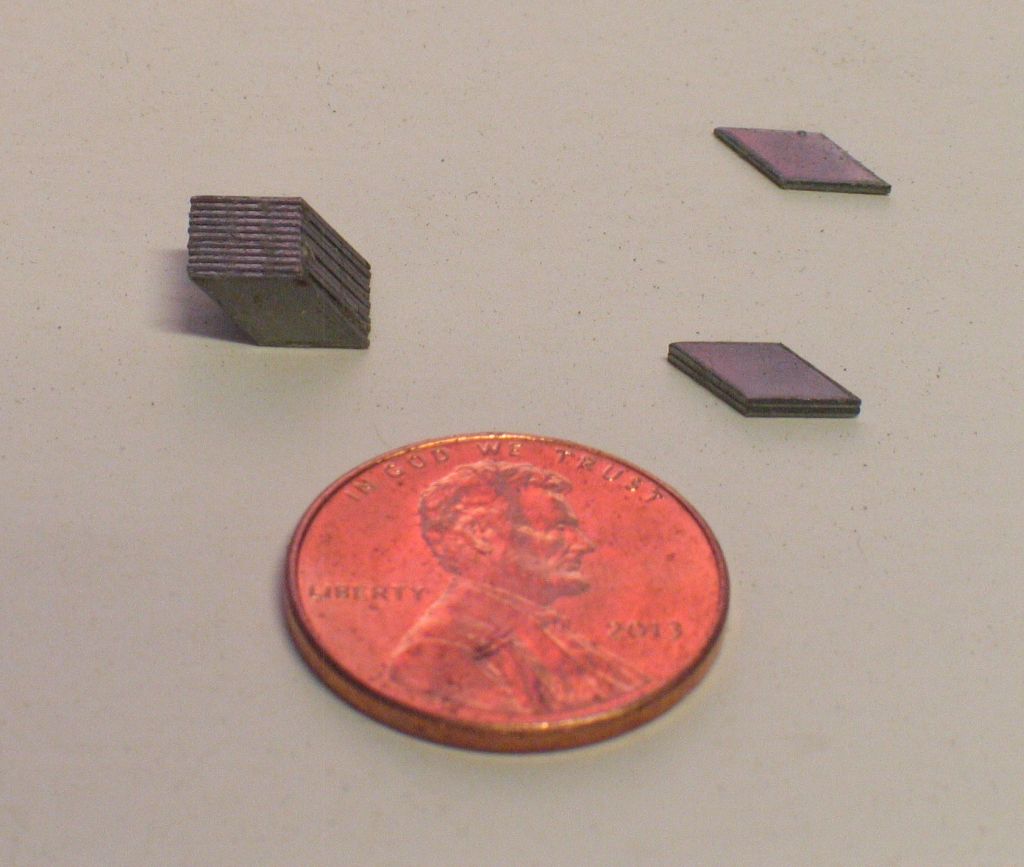

A more “modern” style of glazier’s point is the small diamond-shaped ones, such as those made here in Windsor, Vermont. They were not only small, which made it easier to cover them with putty when they were set, but they were put in place with a setting tool that would be filled with many of them, making the operation much quicker.

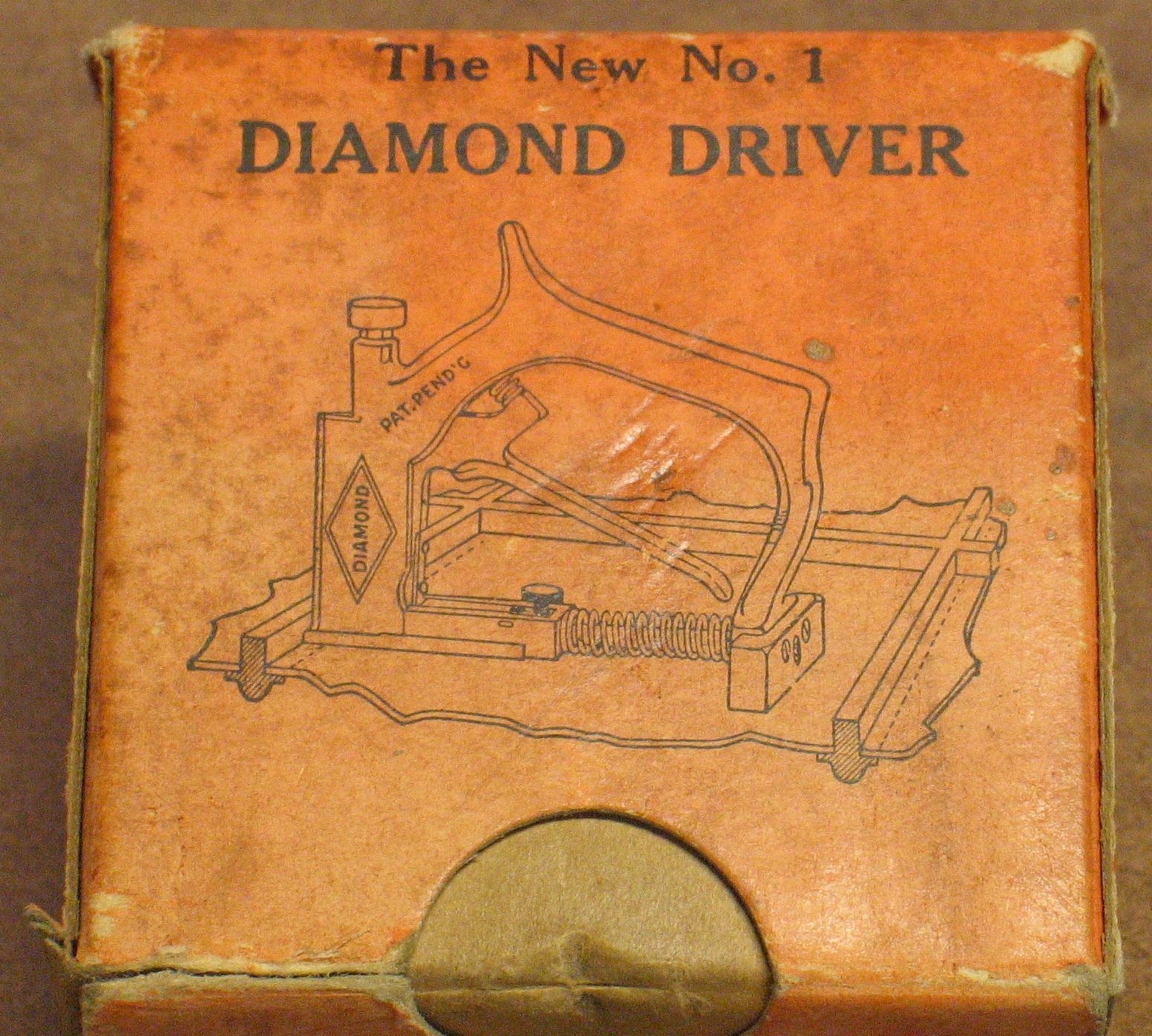

The original versions of these point-setting tools had to be used with the window frame in a horizontal position so that the points would feed properly. Gravity was what fed ’em.

Here is a setting tool with the prototype of a device to apply pressure on the stack of points:

Here is a setting tool with the prototype of a device to apply pressure on the stack of points:

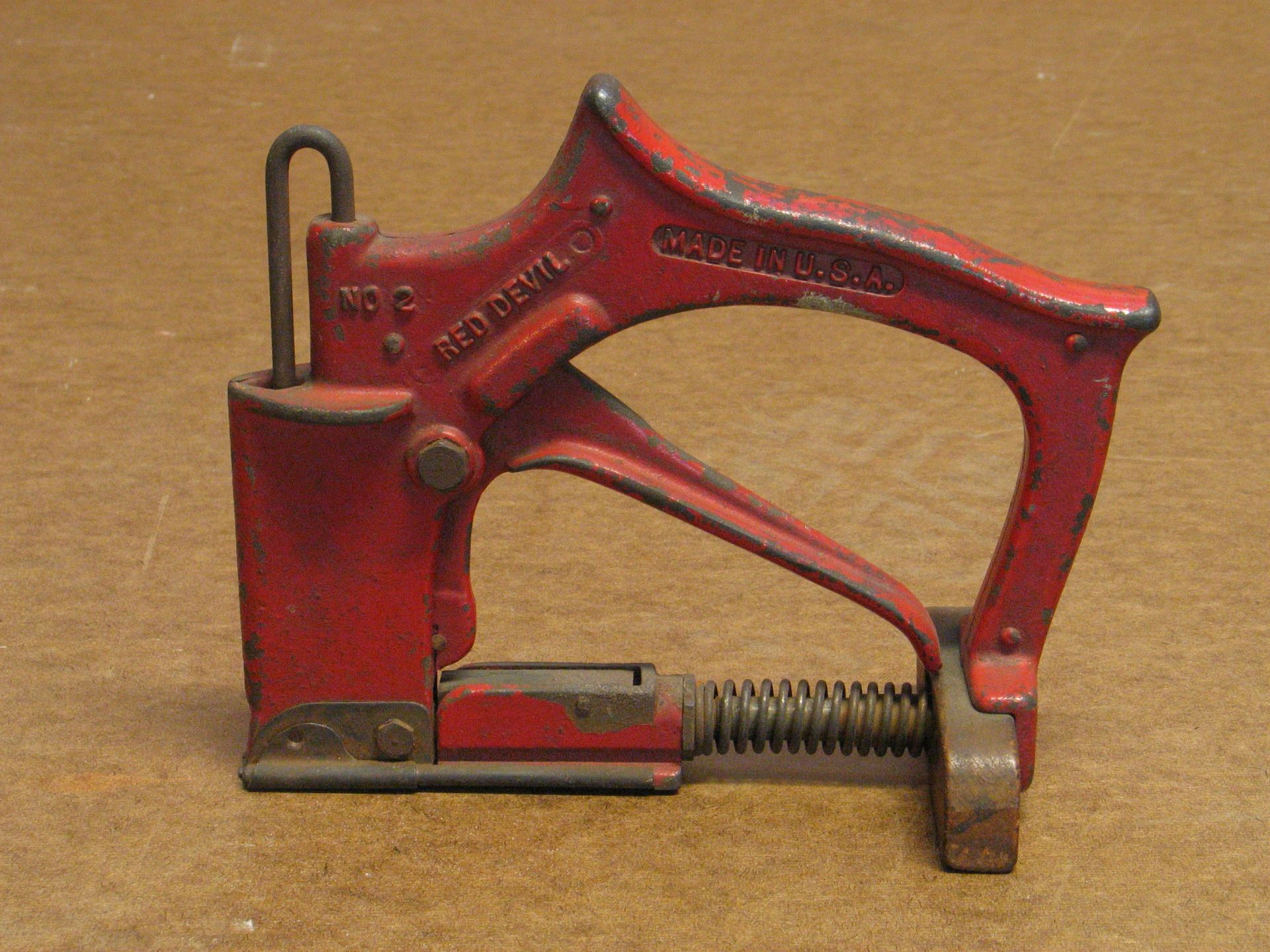

One of the companies that sold tools that were made here for them was Red Devil. They sold all sorts of painting and glazing stuff. The U-shaped device is to press on the points so that they feed reliably.

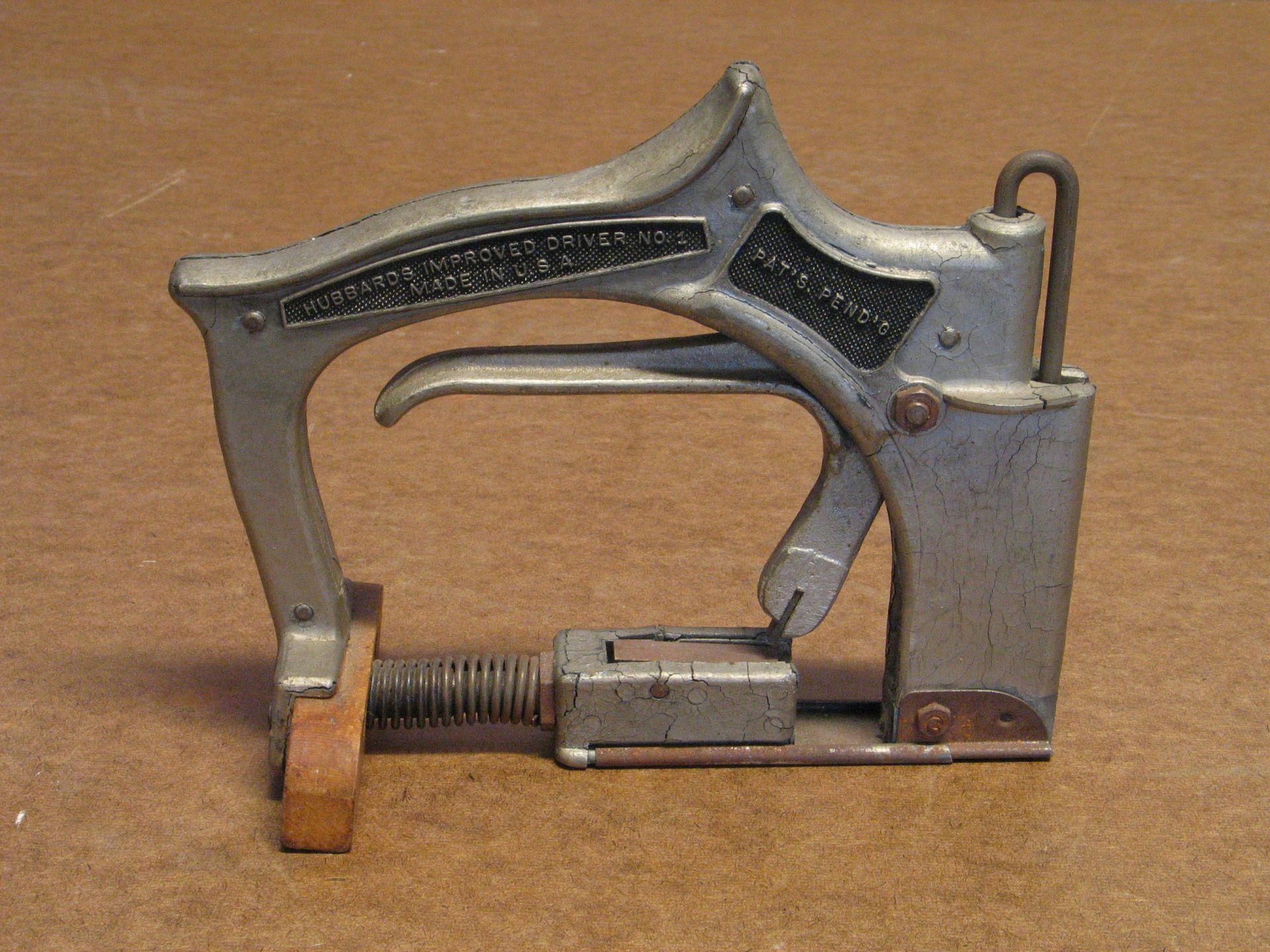

This tool must have looked good when it was new, but that was a while ago. I think that it’s made of zinc, like a toy car. The metal gives great detail when molded, but it’s not stable. Now, it has many serious cracks and will someday crumble completely.

George Hubbard owned the company that made these tools. The company made a handy kitchen scale as well. He also made percolators on which he held a (or the) patent. The box of points says that the company was founded in 1880. The building that housed Hubbard’s shop where the points and their setting tools were made is still here. As seen from Main Street, that’s it with the red wall above and white below. The street leading to it, between the barbershop and the bank, is called Point Shop Lane.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact