Learning Resources

Check out our learning resources portal! From deep dives into the machines from our collections to curriculums for classes, we have an array of free, public materials available/

Learning Lab

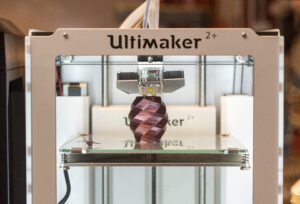

What is the tallest tower you can make using only 20 paper straws and a roll of tape? Can you code a sphero to make it out of our maze? How can you make a model car run on 3 different types of alternative energy? Interested in learning how to design 3D prints?

We use the Learning Lab for field trips, in-house workshops, and group reservations. It’s hands-on and designed for all ages (from “K” through “gray”), where we challenge each other to harness our inner engineers, artists and designers to collaboratively solve hands-on problems. We use everything from building blocks and spheros to co bots and 3d printers. Look at our events page to see if there are any upcoming programs that you’d like to take part in.

Innovation Station

APM interns bring our story to life as they demonstrate the operation of both historic and modern machine tools in our innovation station. See how our state-of-the-art machines work, ask questions along the way, and then take home the objects our interns made from our gift shop. If you’re interested, please call ahead to ensure that we will be running the Innovation Station on the day you want to visit.

The Innovation Station is an integral part of our museum, and it brings our story into the present, helping us not only educate visitors about the history of industrialization and the American System but also inspire the next generation of manufacturers and engineers. These initiatives tie into our core mission: To capture the imaginations of young and old with the spirit of innovation, problem-solving and design demonstrated through the dynamic story of the machines and people that form the foundation and future of manufacturing in America.

The Innovation Station features:

- Haas DT-1 CNC Machining Center/Midaco Pallet Changer

- Fanuc LR Mate 200 iD Articulated Arm Robot

- Bridgeport Milling Machine with HEIDENHAIN Conversational CNC Controller

- Caron Engineering D-Tect It Machine Condition Monitoring System

- Ultimaker 3D-printer