Blog

Machine of the Month: Barnes Lathe (and other machines)

Written by John Alexander, Collections Technician

The sight of an old catalog for Barnes lathes led to this month’s article.

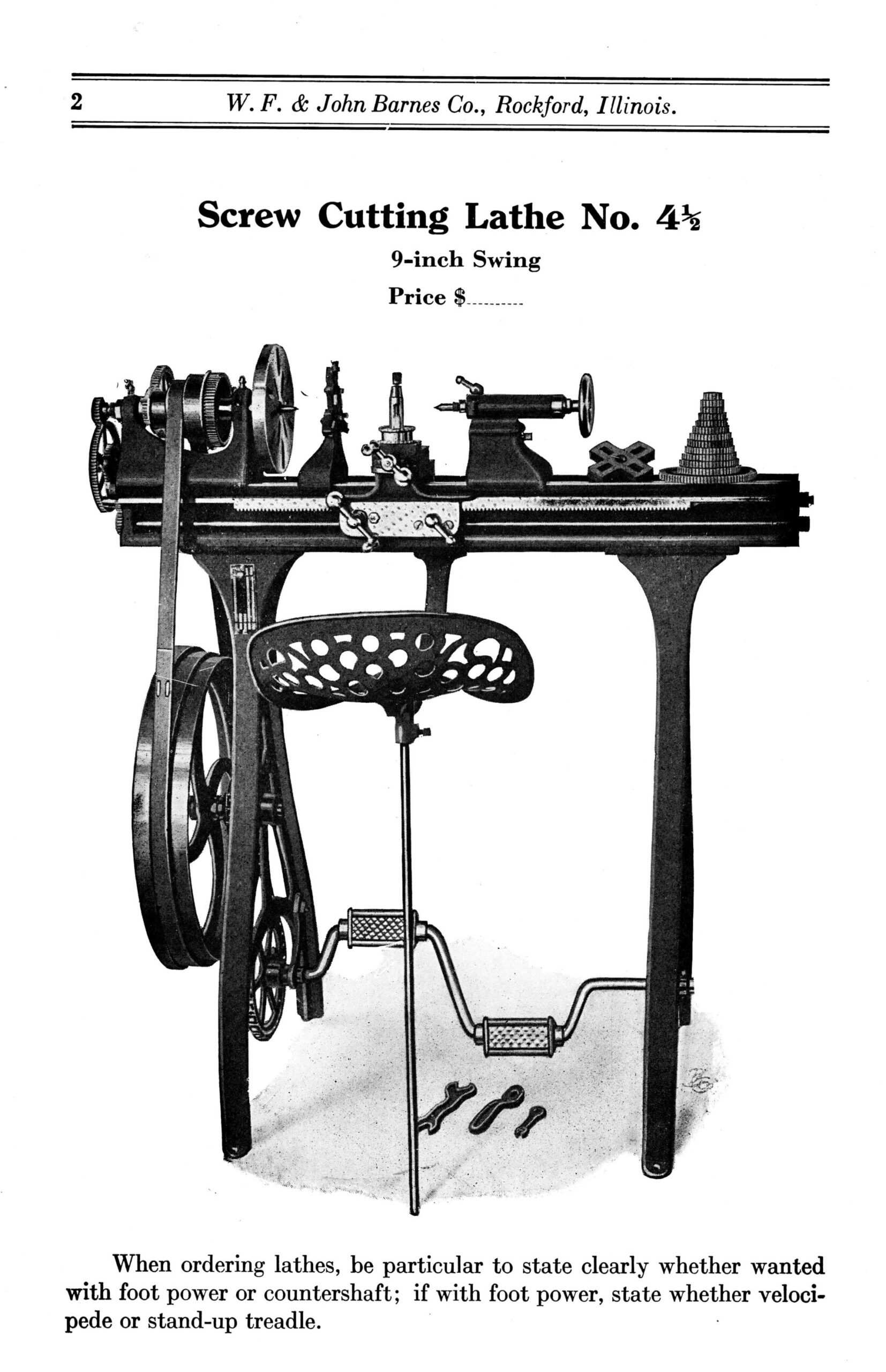

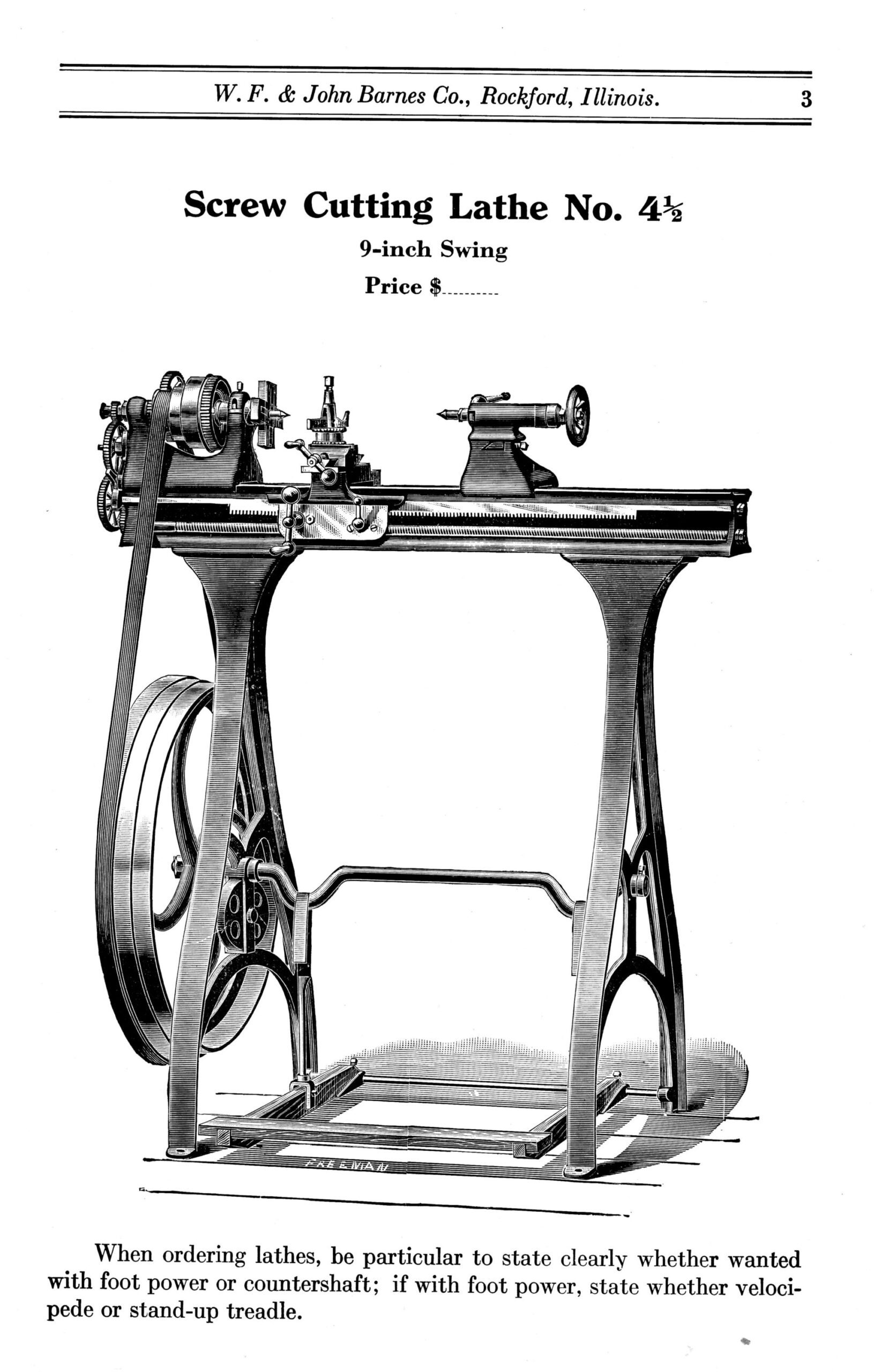

The company was founded in 1872 as the W. F. & John Barnes Company in Rockford, Illinois. Barnes was in business for a long time. This catalog was published in June 1921, but we don’t know how much longer they stayed in business. Although the Barnes machines were offered with countershafts to use power from overhead, they are best known today for foot-powered lathes. I watched a skilled operator cut threads with one at a model show. He and the lathe were quite comfortable with each other, and it couldn’t have been much more effectively done. To move the cutting tool back to the beginning of the threads for another pass, you pedal backward.

Who would need a foot-powered lathe? Farmers would find it especially helpful. By the 1870s, there were a lot of machine parts that a lathe like this could replace. That meant a farmer could get his broken machine back into service faster than having a piece shipped to him. At a much lower expense, too. Note that electricity didn’t come to many places in the United States until well into the 20th century.

Even by 1921, telephones were uncommon in really rural places. Although parts might be in stock, there was no way to contact the dealer quickly if they weren’t in the same area. Of course, other trades could use a moderately priced engine lathe. Blacksmiths and carriage builders come to mind. Rural people would also have appreciated that woodturning could be done on these lathes. Handy for ornamental work or to make pegs to hang things on, repair your furniture, etc.

Our Barnes lathes have pedals. Barnes called the pedal setup “velocipede.” A word popular at the time for “bicycle.”

They also made a unit with a press bar across the front near the floor, designed to be used while standing. This was called a treadle, the same word used for the foot power for sewing machines of that era.

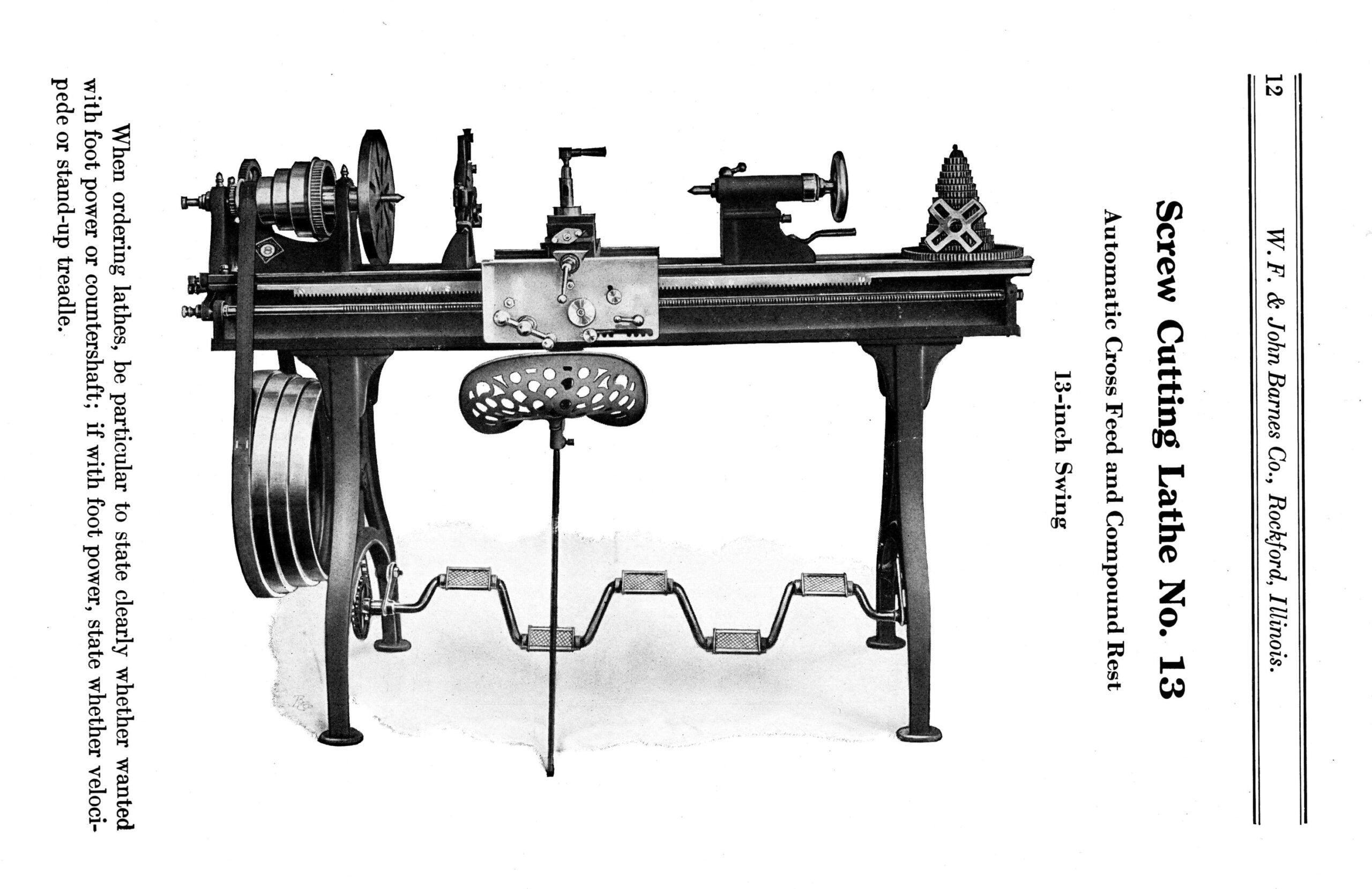

Our lathes each have two pedals. The catalog shows a longer-bedded lathe with five.

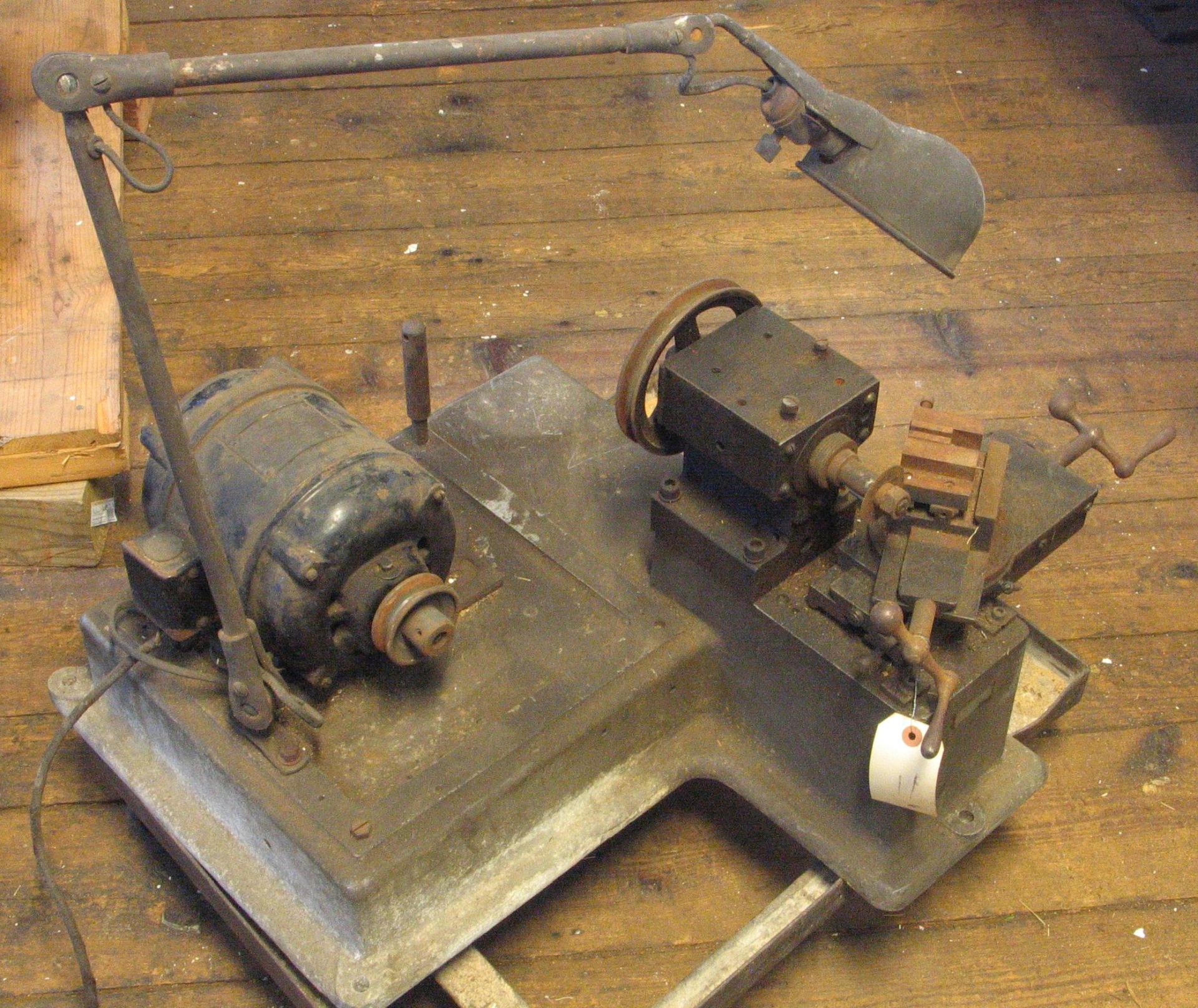

We have four Barnes lathes, but they aren’t on display now. Here is a picture of a Barnes lathe on display several years ago.

We also have a Barnes drill press. It’s a tall, elegant machine. Its last patent was from January 1902. It has a variable-speed drive. It uses two discs. The driving disc is on a horizontal shaft, and the driven disc is on a vertical shaft.

The driving disc is a steel plate, about 9 inches in diameter. The driven disc is made of laminated leather, 6 layers thick, for friction. There’s a finger hook to lift the driven disc across the driving disc to change the speed. This lifting reduces the speed by using the slower-moving center of the driving disc. There’s a locking wheel at the top to keep to your selected speed.

And if that weren’t enough, if the friction disc is lifted past the center of the driving disc, the machine will rotate in reverse! There aren’t many uses for left-hand rotation on a drilling machine, even in a modern shop. When this machine was made, there were probably far fewer.

This picture is from the last page of the lathe catalog. Note that the speed changing is done by shifting the drive belt across the two pulleys. It gives a much stronger drive, less prone to slipping, but it’s not as interesting as the friction drive.

We also have a cute little bench milling machine tagged “Barnes,” but it probably isn’t by this same company. It has no manufacturer’s markings at all.Ken Cope’s book, “American Milling Machine Builders 1820-1920,” has no “Barnes” entry, and Cope was pretty thorough. The motor on this machine isn’t the original one. The motor has a brass tag by the manufacturer: “Refrigeration Motor”! We have some objects of this mysterious sort. They are often interesting, but the inventory tag, which was put on the machine in 1991, isn’t any help in finding out the history of this object.

stay up to date

Want more content from the American Precision Museum?

Sign up to receive news straight to your inbox!

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact